jaw crusher toggle plates

In- depth – Components of a Jaw Crusher | PROPEL INDUSTRIES

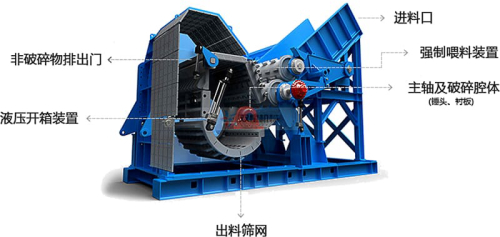

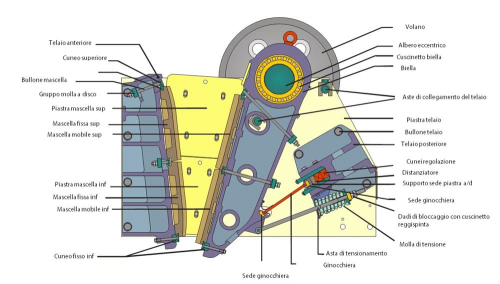

14/06/ · Here, it refers to the moving jaw in a jaw crusher. It achieves the reciprocating movement through the eccentric motion of the flywheel shaft. This creates enormous force in each stroke. The pitman is fitted with two replaceable high strength steel alloy toggle plate. 3.

Learn MoreJaw Crusher Toggle Plate

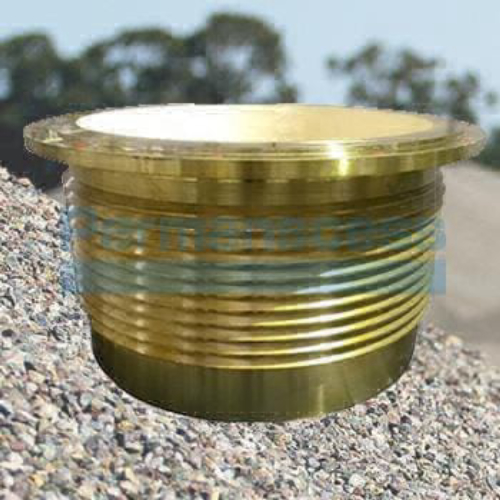

Jaw crusher toggle plate is manufactured with super high manganese steel, therefore it has a service life 50~100% longer than those made of traditional high manganese steel. Every model of PE series jaw crushers is tested for shock, stress, strain, thermal loading, deformation, vibration and noise under a wide range of load conditions.

Learn MoreJaw Rock Crusher Supplies By Trusted Manufacturer - AGICO

A double toggle jaw crusher has two shafts and two toggle plates. When it works, the moving jaw only involves arc swing motion. Single toggle jaw crusher A single toggle jaw crusher has one shaft and one toggle plate. The eccentric shaft is on top of the moving jaw allowing the moving jaw to move in arc swing and up down at the same time.

Learn MoreCrusher Output Adjustment, Shim Plates and Toggle Plate Placement

Check out this amazing educational video on the working principle of a Jaw Crusher, how to adjust output by adding or removing shim plates behind the jaw, and ensuring the toggle plate is in its proper position. The immediate obvious symptom of a dropped toggle plate is low production rate of very small material as the jaw cannot fully open.

Learn MoreSpare Parts of C Series Jaw Crusher | GTEK MINING

C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. GTEK supplies most commonly used spare parts and wear parts for C series jaw crushers, including the most commonly used wearing

Learn MoreGiant Crushing: Jaw Crusher Parts - Giant Crushing

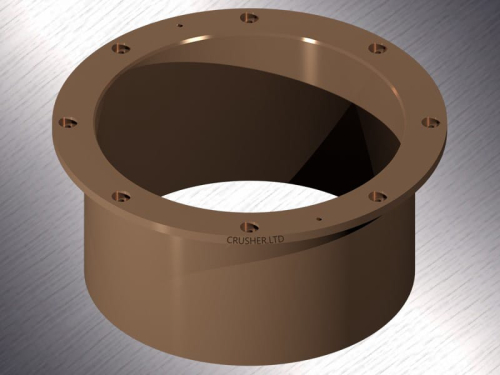

Giant manufacture a range of hard wearing toggle seats and plates that can withstand the high demands of mining and rock crushing. Available in several different sizes to suit different cone crushers, Giant toggle seats and plates can handle great crushing pressures and are also designed for easy replacement to minimize downtime. Order Today,

Learn MoreJaw Crusher Toggle Plates vs. Hydraulic Toggle Relief

A toggle plate basically operates like a fuse. If any material enters a jaw crusher that cannot be crushed, whether due to its size or

Learn MoreJaw Crusher Toggle Plate Manufacturer from Indore

Manufacturer of Jaw Plates - Jaw Crusher Toggle Plate, Manganese Jaw Plates, Roto Jaw Plates and Manganese Industrial Jaw Plates offered by Super Metal

Learn Morejaw crusher toggle plate | spare outer bushing small crusher

Crushing Plant--Jaw Crusher. Jaw Crusher >> E-Mail:[email protected] >> Http://www.joyalcrusher.com Work principle The motor drives the mobile jaw up and down through eccentric shaft. The angle between toggle plate and mobile jaw increases when mobile jaw plate moves up. So the mobile jaw plate closes up the fixed jaw plate. The stuff will be

Learn MoreReplacement Jaw Plates, Cheek Plates, Wedges & Toggles | Unicast

Jaw Plates Cheek Plates Wedges Toggles Toggle Seats Unicast proprietary alloys and innovative designs result in long wear life compared to other OEM replacements. Unicast jaw crusher wear parts are cast using M2, M19, or M22—work hardening alloys for optimum performance. Titanium Carbide (TiC) options are available for even longer wear life.

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 2

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn More