cone crusher sizes

Cone Crusher Market Size: Projected to reach USD 1589.44 million with

The Global Cone Crusher Market Size was estimated at USD 1280.91 million in 2022 and is projected to reach USD 1589.44 million by 2028, exhibiting a CAGR of 3.13% during the forecast period.

Learn MoreAstec Titan® Cone Crushers - Astec

Titan ™ cone crushers are engineered to deliver uncompromising productivity, safety and ease-of-maintenance for maximum uptime in tough, abrasive applications. With four sizes ranging from 200 to 500 horsepower, and capacities from 100 to 760 metric tons per hour, there is a Titan ™ cone for every application. Applications Previous Aggregates

Learn MoreCrushing equipment - UZTM-KARTEX

Crushing equipment · Feed opening size, mm. 500 - 1600 · Rated discharge opening width, mm. 75 - 250 · Max. lump size of feed, mm. 400 - 1500 · Max. lump size of

Learn MoreCH430 Cone Crusher Suitable For Secondary Applications

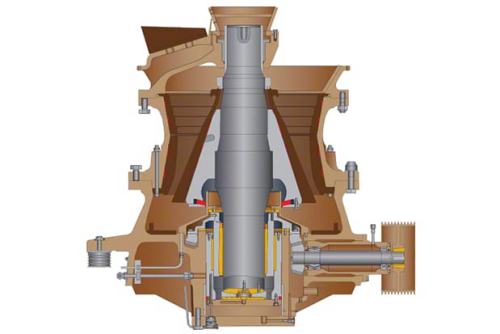

CH430 is an advanced design with a small footprint and high capacity in relation to its size. This cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. Email us Request a quote.

Learn Morequarry cone crusher feed size 50mm

2022/9/14 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn MoreCone Crusher Sizes | Crusher Mills, Cone Crusher, Jaw

automax 1000 cone crusher max feed size – Grinding Mill China. OPS Screening & Crushing Equipment. Jaques World Class 42×30 Jaw Chamber. 650mm max feed size. up to 500T per

Learn MoreCone Crusher Manufacturer

Cone Crushers is suitable for crushing all sorts of ores and rocks whick crushing cone, which will unavoidably influence the size of discharge,

Learn MoreJaw Crushers - high quality and reliability from RETSCH

The jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600.

Learn MoreWhat is a cone crusher mantle? - Sandrock Mining

Cone crusher concave and mantles are the main factors that determine the size of the discharge opening. When the cone crusher is under load, concave, mantle and the stone make circular motions, causing wear, so it is necessary to adjust concave and mantle gap to control the granularity of the finished product.

Learn MoreCone Crushers Market Share, Size and Forecast 2022-2027

A cone crusher is a mechanical device used to reduce the size of large rocks. It is widely used in the construction and mining industries to crush hard and abrasive materials, such as river gravel, basalt, granite, iron, chrome, magnesite, and copper ores. 5 Global Cone Crushers Market 5.1 Market Overview 5.2 Market Performance 5.3 Impact

Learn MoreChoosing the right crusher - Buying Guides DirectIndustry

The cone crusher cannot take material of all sizes. The materials must be pre-dimensioned for the crusher (usually 200 mm or less). The finished product is not homogeneous, which is an essential requirement for many material specifications.

Learn More