grate kiln

Grate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

There are various types of clinker coolers developed before grate cooler: shaft cooler, rotary cooler, etc. Compared with them, grate cooler is the most suitable one for cement production lines with high outputs and usually designed for large cement kiln capacity that up to 10000 t/d. Distinct advantages of grate cooler:

Learn MoreContributions to The Technology Comparison Between Straight Grate and

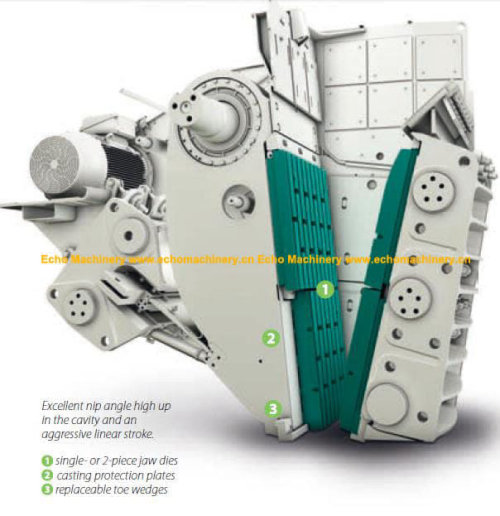

The grate-kiln process, which has been inspired from furnaces designed in the cement industry, uses three distinct pieces of equipment to carry out the induration process: a preheat travelling grate, a rotary kiln, and an annular or straight cooler. Drying and preheating of the green pellets is accomplished on the preheat grate,

Learn MoreCN106268270A - A kind of grate kiln denitrating system - Google Patents

The invention discloses a kind of grate kiln denitrating system, including the first preheating section and the second preheating section for heating pelletizing, also include the denitrification apparatus for removing nitrogen oxides in effluent, described denitrification apparatus is located at described second preheating section inner chamber, this denitrification apparatus can not only

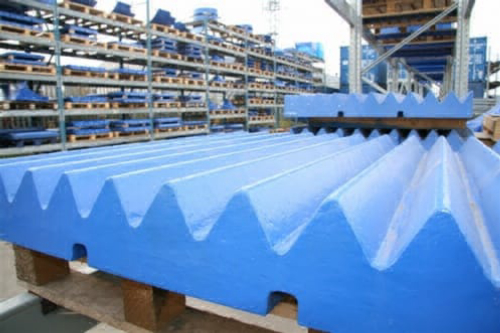

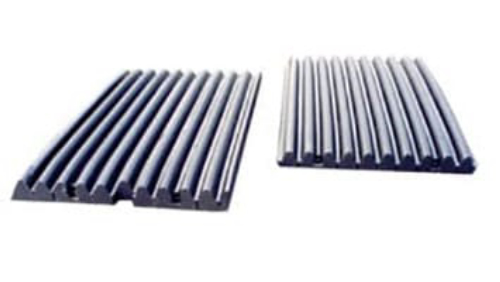

Learn MoreTravelling Grates&Chain Grate&wear plate on Grate-kiln

2022. 5. 28. · Casting process: Shell mold precision casting. 2. Steel grade: 1.4777 1.4848 1.4837. 3. Dimensional Tolerance of cast: DIN EN ISO 8062-3 grade DCTG8. 4. Geometrical Tolerance of cast: DIN EN ISO 8062 – grade GCTG 5. 5. Application: Wear Parts on Grate-kiln.

Learn MoreGrate preheater kiln system - Allis-Chalmers Corporation

The reinforced direct-fired grate preheater kiln system to be described can supply the additional heat to the grate preheater for accomplishing more preheating, that is calcining, which permits treating a higher temperature solid in the kiln which can be designed to hold the material at a temperature for a predetermined time for controlled

Learn MorePelletizing Process

2011. 1. 6. · Grate-Kiln-Cooler process allows independent operation adjustment of grate, kiln and cooler, which enables the operators ; a) to, easily and without any risk, decrease and increase the rate of pellet production. b) to overcome radical changes in the characteristics of iron ore materials fed to the

Learn Moreto supply large-scale grate-kiln pellet plant to India - SteelOrbis

Finland-based global engineering and technology company Outotec Corporation has announced that it will supply a large-scale grate-kiln pellet plant to an Indian customer in Odisha. The value of the order is estimated to be in the range of €30-40 million. According to the statement, the grate-kiln plant with an annual production capacity

Learn MoreGrate Kiln For Sale – Grate Kiln System | AGICO Grate Kiln

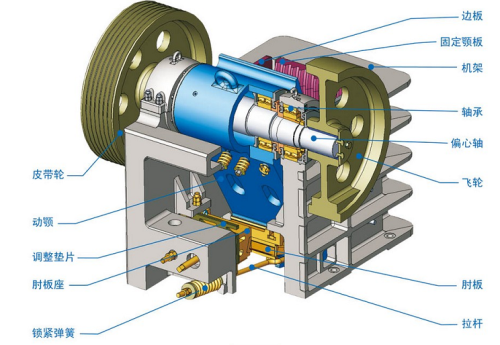

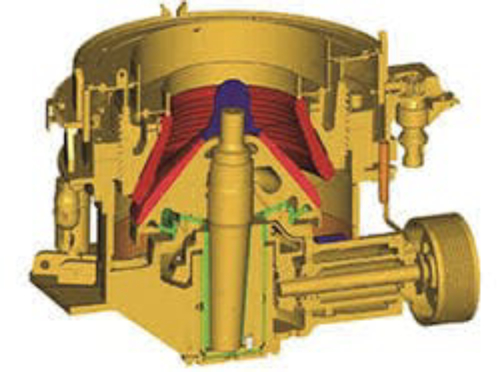

The grate kiln system consists of three independent machines: traveling grate, rotary kiln, and annular cooler. Operators can separately control the running speed of the three devices. It

Learn MoreOverall comparison of straight grate (SG) and grate-kiln (GK

Schematic of the two principle pelletizing processes: (a) straight grate pelletizing process (Mourão, ); (b) grate-kiln pelletizing process ( , ) Currently, the existing

Learn MorePDF Case study of grate-chain degradation in a Grate-Kiln processPDF

Schematic overview of the Grate-Kiln process (to the left) and a grate-link before service (to the right). A is the grate-chain and B is the rotary kiln. C, D, E and F are different heating stages

Learn Moreto supply large-scale grate-kiln pellet plant to India

2021. 4. 9. · Finland-based global engineering and technology company Outotec Corporation has announced that it will supply a large-scale grate-kiln pellet plant to an Indian customer in Odisha. The value of the order is estimated to be in the range of €30-40 million. According to the statement, the grate-kiln plant with an annual production capacity of six

Learn More