grate cooler pdf

PDF 13GREENID A Self-tuning Fuzzy PID Control MethodPDF

the control model of grate cooler was obtained by system identification. It was shown that this method could inhibit the influence of noise of pressure signals, could enhanced adaptive capability of controller and could improved heat energy recovery efficiency of grate cooler. Keywords: self-tuning fuzzy PID, Kalman filter, grate cooler 1.

Learn MoreClinker cooler replacement delivers improved productivity at

to the grate cooler, which was an older generation with low thermal e ciency, and high-energy consumption and requiring more maintenance.

Learn MoreResearch on Modelling of Grate Cooler Based on Typical

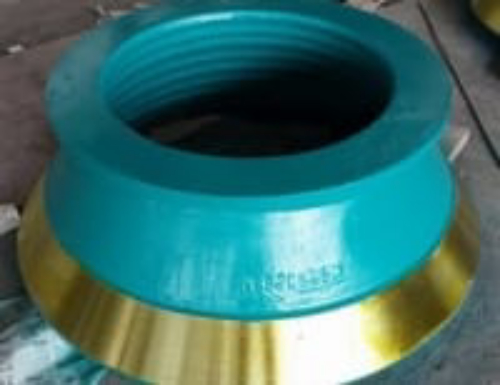

The grate cooler is the main equipment for clinker cooling and heat recovery in the sintering process of cement clinker, and maintaining the grate cooler.

Learn MoreGrate cooler for a cement clinker kiln - EP 2559961 A1

for cooling and transporting of cement clinker and grate onto a grate cooler where it is cooled by cooling air and.

Learn Moreperformance evaluation of a grate cooler in a cement ... - IJSEAS

The cooler efficiency was found to be. (75.53%) at this stage of the clinker production process. This study revealed that the grate cooler

Learn MorePERFORMANCE EVALUATION OF A GRATE COOLER IN A

The grate cooler heat radiation was measured using infrared thermometer (561-566 nanometer wavelength). This compared the surface temperature to the surface area and values obtained were tabulated on Table 3.3. 3.2 Calculation Basis for Mass and Heat Balances. Basis for material: one (1) kg and 0℃ of clinker is usually taken as the basis. 3.2.1 Cooler Mass and

Learn MorePDF designer and Manufacturer Company in Iran. - GreenIDPDF

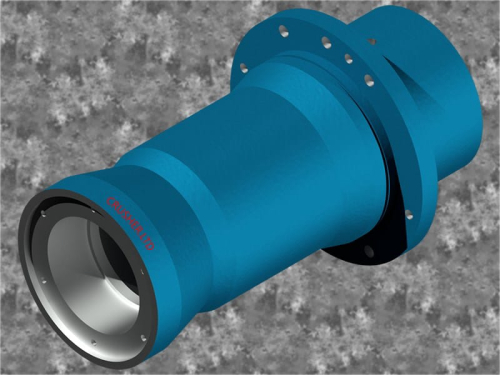

The grate is driven by cylinders placed on either side of the cooler. The hydraulic drives consist of axial piston pumps with electro hydraulic servo adjustment of the oil flow to the cylinders which have built in linear transducers. The system is controlled by a PLC .The pump units have built flow and its direction.

Learn MoreThe energy optimizers - ABB

the air into the grate cooler to reduce the temperature of the hot clinker leaving the kiln 1 . All these airflows have to be adjusted and controlled as.

Learn MoreConversion to High-Efficiency Grate Coolers

The grate cooler is integral to heat recovery from the clinker, so grate coolers that operate with higher efficiencies will lead to less wasted heat and

Learn MoreGrate kiln pelletizing plant - Outotec

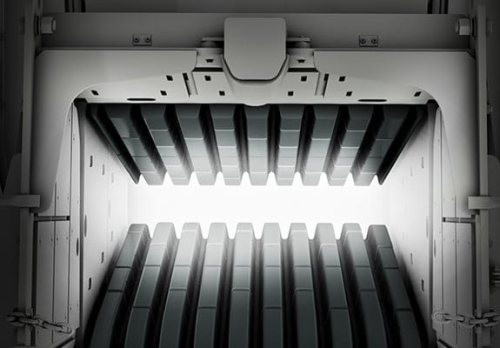

The Grate, the Kiln and the Cooler. The object of the process is to transform the pelletized concentrate into hardened pellets that can be used as blast furnace feed or direct reduction furnace feed. The Travelling Grate is where pellets are dried and then heated up to a temperature of about 800-900 deg C. The heat used to dry and preheat the pellets is typically hot air pulled

Learn MoreGrate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

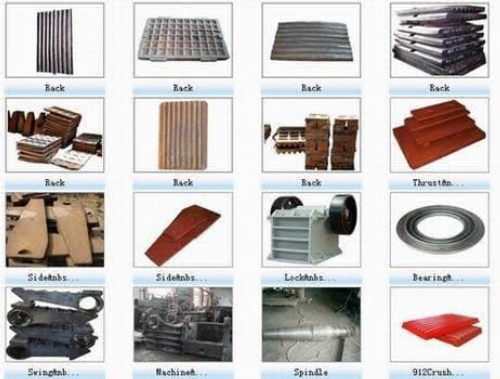

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan. Of these devices, grate bed is the most important part, mainly composed of overlapping rows of static and movable perforated grate plates.

Learn More