grate cooler design

Impact of Specific Number of Air to Clinker on Clinker Cooling

Clinker cooling process is a complex process due to the vast number of adopted in the scaled conceptual design after an existing running clinker cooler.

Learn MoreMaintenance Of Under Grate Pressure in Grate Coolers

A design of Internal Model Control based PID controller for maintaining the under grate pressure of a grate cooler used in cement plants is presented in

Learn MoreD9.2 Analysis of oxyfuel clinker cooler operational performance

performance (efficiency), as well as the potential impacts of CO2–rich cooling gas on clinker quality. The oxyfuel clinker cooler prototype was designed

Learn MoreClinker Cooler Unit - FONS Teknoloji

Fons Delta Cooler has been designed in a very smart and compact way; with this compact design, it can respond to the needs of each cement plant separately.

Learn MoreGrate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

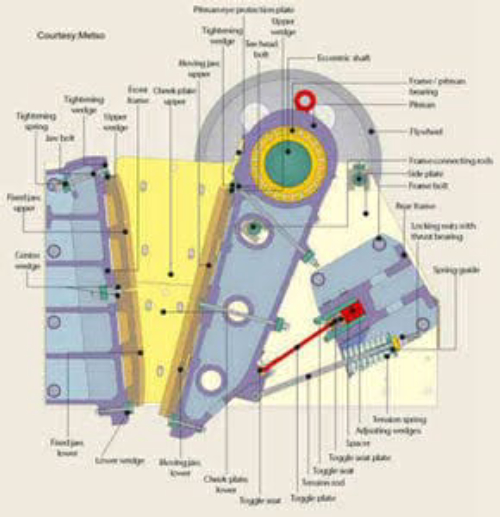

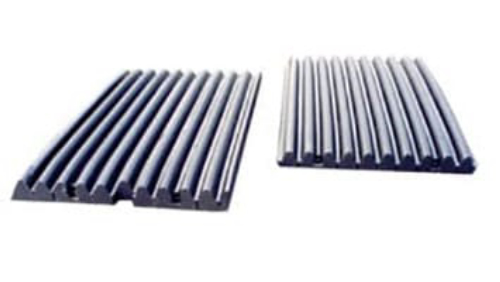

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan. Of these devices, grate bed is the most important part, mainly composed of overlapping rows of static and movable perforated grate plates.

Learn MoreGrate Kiln System

Oct 14, · Initial GRATE-KILN plants were designed with no heat recuperation systems and typically consisted of a two pass, downdraft drying and downdraft preheat grate cycle. A preheat bypass system was installed to complement the preheat off-gas supply so that these two streams delivered the required downdraft drying heat supply.

Learn MoreMulti-objective optimization design of air distribution of grate cooler

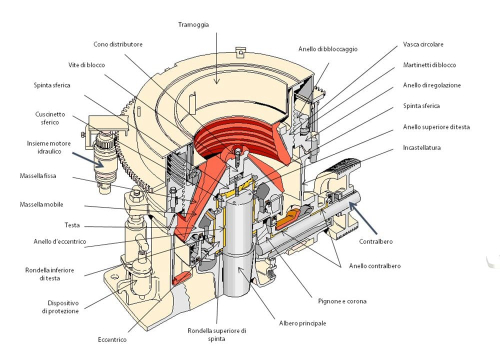

Grate cooler plays a very important role in cement production line whose main functions are quenching high temperature clinker and redistributing the exhaust hot air as shown in Fig. 1 (a). Increasing clinker cooling efficiency has great effects on decreasing power consumption of cooling fans and improving quality of clinker.

Learn MorePDF Pan Conveyors - AumundPDF

between cooler and clinker stock especially for applications with grate coolers. The design allows the Pan Conveyor to be arranged underneath the whole cooler length and to collect the fines from the dust collecting hoppers same as the clinker from the crusher. Installed underneath the clinker stock in combination

Learn Moremodelling of clinker cooler and evaluation of its performance

The design model was scaled down to a ratio 25:1, that is, existing cooler twenty-five (25) and model (Test rig) one (1). The scaling down was based on

Learn MoreRU2489660C1 - Grate of grate cooler of shearing type - Google

FIELD: metallurgy. SUBSTANCE: grate of a grate cooler of shearing type includes a horizontal base and a working plate of straight-line shape with through passes for cooling air, which is inclined to it; at that, in the working plate there are cavities that in a vertical longitudinal grate plate section have the shape of triangles adjacent to each other so that alternating cavities and

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant Equipment

The grate cooler adopts a modular construction design, is flexibly adaptable to different scales of the cement kiln. There is no need of conveying equipment for material leakage under the grate bed. The adjustment and optimization of the grate bed help to cool clinker uniformly. High thermal efficiency. High conveying efficiency.

Learn More