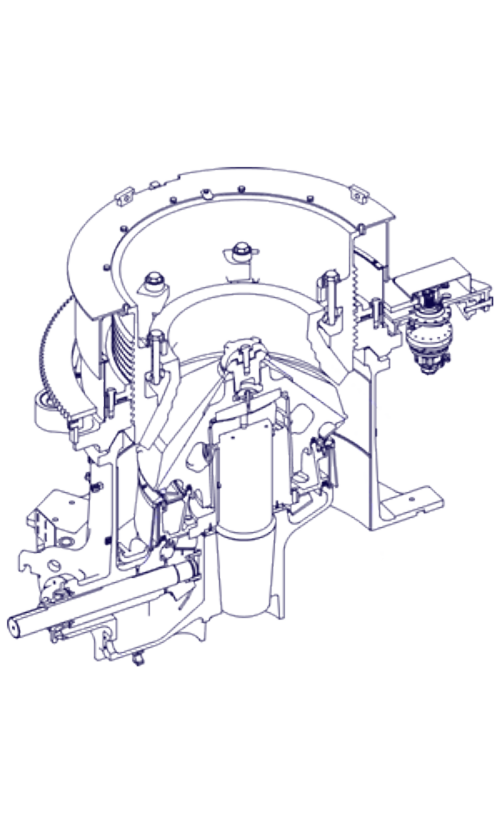

jaw rock crusher design

Source The Ideal Wholesale jaw rock crusher design

New designjawCrushermobile aggregate rockcrushing line for 200tph granite crushing plant,same as Mesto crushercheap price $6,000.00-$150,000.00/ Unit 1.0 Units(Min. Order) 10YRSCN Supplier Contact Supplier 1/6 stone crushermachine price /jawcrusherprice list /jawrockcrusherdesign Up to 5 years warranty $800.00-$8,500.00/ Set 1 Set(Min. Order)

Learn MoreHow does a Rock Crusher Work - Jaw Crusher

A jaw crusher frames are of sectionalized construction to facilitate handling. This design minimizes heavy lifts makes the crusher suitable

Learn MoreMaterial Selection for Crusher Jaw in a Jaw Crusher Equipment

The purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the

Learn MoreSmall Scale Mechanized Stone Crusher, Mechanical Design

jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanism.

Learn MoreDesign and Construction of Rock Crushing Machine from Locally

The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid

Learn MoreJaw Crushers VS. Impact Crushers - AL Blair Construction

The jaw crusher design includes a set of two vertical jaws—a fixed (stationary) jaw and a swing (reciprocating) jaw. The swing jaw moves back

Learn MorePDF "Computer Aided Design of Jaw crusher" - National Institute of ...PDF

opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock.

Learn MoreA REVIEW - African Journals Online

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A after blasting of rocks and breaking of oversize rocks or.

Learn MoreTwo Design Awards for Kleemann EVO2 Crushing Plants

The German Design Award and Good Design Award for new mobile jaw and cone crushers of the new EVO2 generation. With these awards, Kleemann has once again

Learn MoreJaw Crusher - JXSC Machine

Jaw Crusher. 【Capacity】 1-130tph. 【Feeding Size】 <1200mm. 【Output Size】 10-300mm. 【Crushing Materials】Granite, dolomite, river pebbles, quartz, calcite, and other materials. 【Application】 Jaw crushers are mainly used at the primary stage to reduce hard and brittle materials size for the next crushing stages, widely applied

Learn MoreDESIGN AND OPERATIONS CHALLENGES OF A SINGLE

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A REVIEW Performance optimization of jaw-type rock crushing machine

Learn More