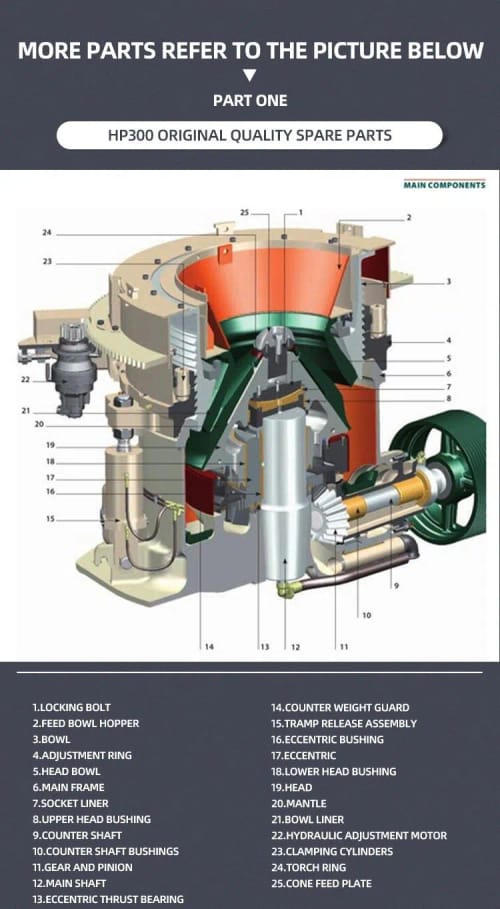

part of jaw crusher

Jaw Crusher Explained - saVRee

Jaw Crusher Components · Fixed Jaw · Moving Jaw · Jaw Liners · Main Shaft (Pitman Assembly) · Drive Pulley & Flywheel · Toggle Plate(s) & Tension Rods/Assembly.

Learn Morejaw crusher spare parts - IndiaMART

We Supply Spare Parts & Wear Parts of Jaw Crusher i.e.Jaw plate moving, Jaw plate fix, Side Liners, Cheek Plates, Upper & Lower Wedges, Wedge bolts,

Learn MoreJaw Crusher Parts Catalog - Zhejiang Gravik Machinery and Equipment Co

The jaw crusher is a crushing machine that uses the squeezing and bending action of the two jaw plates to crush materials with various hardness. The crushing mechanism is composed of a fixed jaw plate and a movable jaw plate. When the two jaw plates are close, the material is crushed.

Learn MoreIn- depth – Components of a Jaw Crusher - Propel Industries

1. Crusher Body · 2. Pitman · 3. Jaw Plate · 4. Rear end frame · 5. Eccentric Shaft · 6. Flywheel · 7. Jaw Crusher Bearings · 8. Toggle Plate.

Learn MoreParts Of Jaw Crusher

Parts Of Jaw Crusher - Factory, Suppliers, Manufacturers from China We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for Parts Of Jaw Crusher, High Manganese Steel, Jaw Plate, Mill ring,Crusher Plate. Welcome all nice buyers

Learn MoreJaw Crusher Parts - Wear Parts For Industry | Qiming Casting

When it comes to jaw crusher parts, Qiming Casting has been crushing the market for decades. If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed, and warranted replacement parts for your jaw crusher. Qiming Casting can supply jaw crusher parts with the best quality and suitable price.

Learn MoreJaw Crusher Parts - Casteel Foundry

the common repalcement wear parts of jaw crusher is jaw plates, side plate /cheek plates, jaw wedges, toogle plate, toogle bearing and toogle seat, the jaw plates consist with fixed jaw tooth and swing jaw tooth which the fixed jaw is wearing bit faster then the swin jaw ,and cheek plates having the left and right, upper and lower which the lower

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

The lubrication of the interface between the parts of the jaw crusher is very important. It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life. Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be

Learn MoreJaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn MoreJaw Crusher Components & Parts - Mineral Processing & Metallurgy

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how they all go together.

Learn MoreJaw crusher maintenance | Henan Deya Machinery Co., Ltd

Elimination methods. 1. The sound of metal impact is heard during jaw crusher operation, jaw plates shaking. The crushing chamber jaw plates are loose, the fixing bolts are loose or broken. Stop the jaw crusher, check the fixation of jaw plates, and use hammer to tighten the wedge on plates, then fasten the bolts or replace the bolts if they

Learn More