compression spring manufacturing process

Compression Springs - Stock and Custom | Shop Now - MW Components

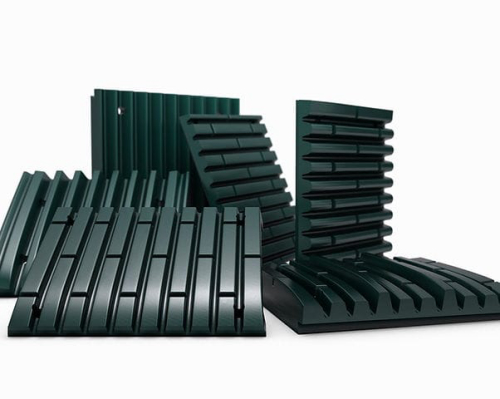

Our compression springs can be manufactured with a selection of commonly requested or specialty finishes and processes. Finishing processes may include grinding, shot peening, and heat setting. Finishes may include Finish Black Oxide Passivation Powder Coating & Color Coding Rubber Plating (Zinc, Nickel, Silver, Tin & Gold Electroplating)

Learn MoreHelical / Compression spring manufacturing process - Blogger

There are total Eight steps which are required in making propeller shafts · Pattern Making · Molding · Casting · Fatling · Machining · Grinding · Balancing · Surface Finishing Pattern Making - It is a process where from the design of the propeller shaft we make the similar pattern of Fibre glass and putty.

Learn MoreHow Coil Spring Manufacturing Works

Coil spring manufacturing processes are used in the production of a variety of springs. The familiar shaped compression spring,

Learn MoreSprings Manufacturing - Quality Spring, Affordable Prices

This process is whats referred to as "closed and ground ends" on a compression or coil spring. It is where half the wire on each end is ground off so that the

Learn MoreCustom Compression Spring Manufacturer - Helical Springs | Coiling

Certified ISO 9001 manufacturer of custom-crafted small or large coil springs, compression springs , extension springs , suspension springs , wave springs, and torsion springs. Capacity to deliver any size order out of our 110,000 square-foot facility in Houston, TX from prototype runs to high-volume orders.

Learn MoreCompression | Rockford Spring

This insures an efficient cost effective process that will meet the most demanding requirements. A variety of materials are used when manufacturing compression springs, including hard drawn, music, oil-tempered, chrome silicon, stainless, and other available types of spring wire. Our wire size range is from a minimum of .006 diameter material

Learn MoreThe Physics of Springs: How Manufacturers Design Springs

Hooke's Law states that the more you deform a spring, the more force it will take to deform it further. Using the example of a common compression spring, the

Learn MoreInformation compression springs - Gutekunst Federn

Compression springs are made from round, oval or square spring steel wires. Most of the spring steel wire is brought into any desired shape in

Learn MoreCompression Spring Manufacturing

20/08/ · While the vast majority of people only think about springs that they see in their daily lives, if then, springs are used in a number of applications and exis

Learn MoreCompression Spring Manufacturing - Southern Spring and Stamping, Inc

How are Compression Springs Manufactured? When compression springs are manufactured, they start with a design based on Hooke's Law: F = -kΔx. In this equation, force (F) is measured as the displacement of the spring from its default position (Δx), multiplied by the negative of the spring's constant (k).

Learn MoreInside the Spring Production Process - Yost Superior

It all start with design. You choose the material and finish, then provide with your spring specification, and we will get to work designing a

Learn More