how to size a cone crusher

How much is A Cone Crusher? - Luoyang Dahua Crusher

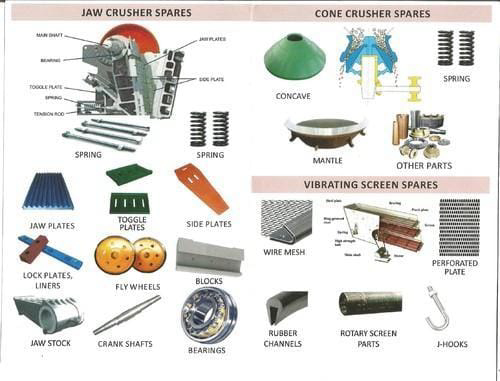

10/08/2022 · Single cylinder cone crusher Multi-cylinder cone crusher Cone crusher advantages: 1. Reduce downtime Due to the safety device, it greatly reduces the downtime. At the same time, the body is a cast steel structure, and reinforcement bars are arranged in the heavy load parts. 2. High production efficiency

Learn MoreCalibration and Validation of a Cone Crusher Model ... - MDPI

Accurate dynamic models of a mineral processing plant are helpful in control system development, equipment sizing, and operator training [1].

Learn MoreHurricane Fiona

To form the cone, a set of imaginary circles are placed along the forecast track at the 12, 24, 36, 48, 72, 96, and 120 h positions, where the size of each circle is set so that it encloses 67% of the previous five years official forecast errors. The cone is then formed by smoothly connecting the area swept out by the set of circles.

Learn MoreCone Crusher Market Future Scenarios, Growth and Analytical Insights

The global cone crusher market is expected to surge at a steady CAGR of 2% during the forecast year of to 2030. The demand for cone crushers will be driven by rise in mining activities. Cone crushers are used for crushing sandstone, limestone, granite, iron ore, and other minerals for further processing. Rise of Construction Industry to Fuel Demand for Cone Crushers []

Learn Moredimensions of a cone crusher - Sebocom Construction

How to Size a Cone Crusher Motor Cone Crusher Motor Sizing. Hard limestone, having an impact strength of 15, is fed from a secondary crusher set at 3¼-in. open side setting, producing stone having 80 percent minus 3¼-in. The product of the secondary crusher is screened at 5/8-in.

Learn MoreCone Crusher Configuration - How Setup Your Crusher For Optimum Performance

Since CSS is affected by we the mantle and concave it is important to measure and adjust frequently, in most cases daily. The CSS effect on gradation is as it becomes smaller the gradation gets finer, see Figure 6. Figure 6. Crusher operated on 16 mm, 18 mm, and 20 mm (from left to right curve).

Learn MoreThe Feeding Size Of PYB900 Spring Cone Crusher

The pyb900 spring cone crusher feed size is 115mm. It is suitable for secondary crushing of hard rock in stone crushing plant.

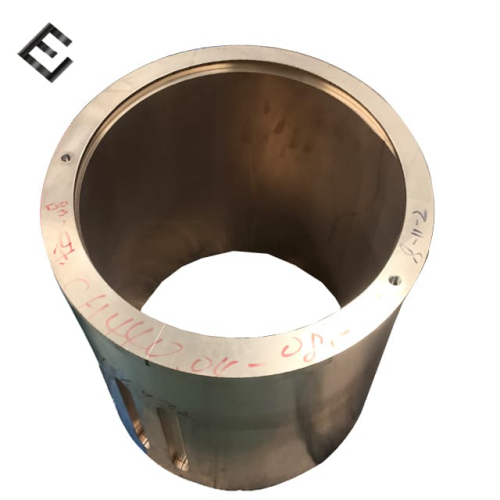

Learn MoreCone crusher - AZTECH

Depending on the specific cone crusher, the maximum feed size is up to 300 mm, resulting in a finished product with a grain size of between 3 mm and 60 mm

Learn MoreHow to Size a Cone Crusher Motor - Mineral Processing & Metallurgy

Multiply the product from step (9) by the tons per hour to obtain the gross hp required. Cone Crusher Motor Sizing Hard limestone, having an impact strength of 15, is fed from a secondary crusher set at 3¼-in. open side setting, producing stone having 80 percent minus 3¼-in. The product of the secondary crusher is screened at 5/8-in.

Learn MoreChoosing the right crusher - Buying Guides DirectIndustry

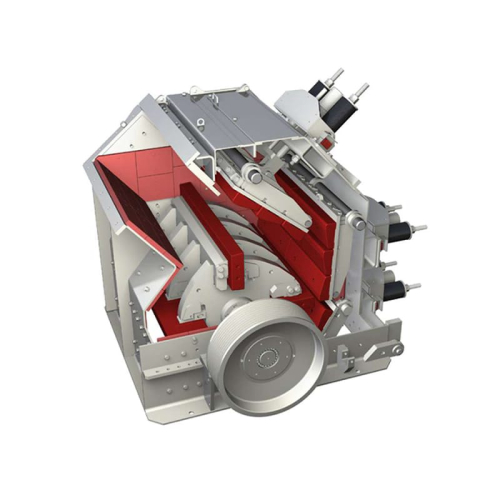

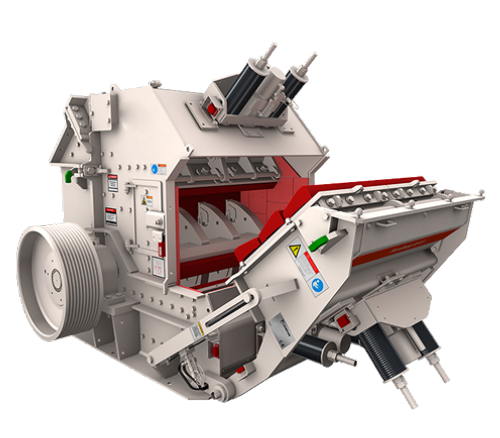

Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing. It is designed to crush pre-dimensioned materials, generally of 100 mm, 150 mm or 200 mm, and provide finished products of small dimensions. Advantages: Sturdy construction High productivity Easy adjustment

Learn MoreHigh-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

Crushes Meter-size Rocks Down to Millimeter-size Rocks. Aggregate quarries and mining

Learn More