roller crusher design

Roller Crusher Design-roller Crusher

Roller crusher design crusher mills cone crusher jawroller crusher design crusher mills cone crusher jawRoller crusher pgroller crusher pg specificationsprice 3 compact design 4 environment protection 5 long life application of roll crusher roll crusher can be applied in industrial sectors such as ore dressing, roller crusher design

Learn MoreDesign Of Roller Crusher - Gravel And Sand Making Machine

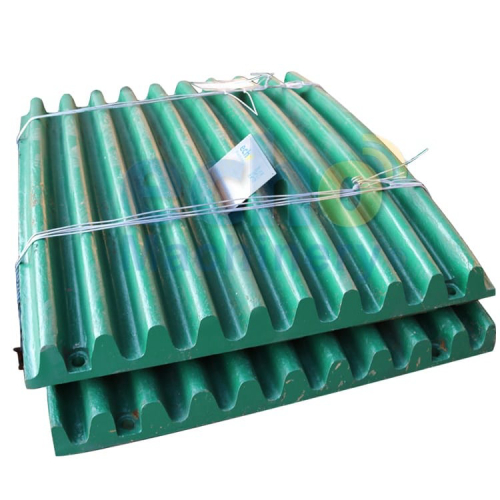

Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact, shear, and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusher.::: 6.2.3 Roll crusher circuit design. Roll crushers are generally not used as primary crushers []

Learn MoreRoll Crusher Manufacturer | Propel Industries

New generation Roll Crusher has been designed using latest engineering tools for high reliability. View Product! Its features and the unique design help manufacture sand at lowest possible power consumption and liner wear cost. Roller Width: mm: 760 (inch) (30.0) Feed Size (Max.) mm: 45 (inch) (1.8) *Capacity: TPH: 50 - 150: Gap Range

Learn MoreCrusher Tooth Design | Crusher Mills, Cone Crusher, Jaw Crushers

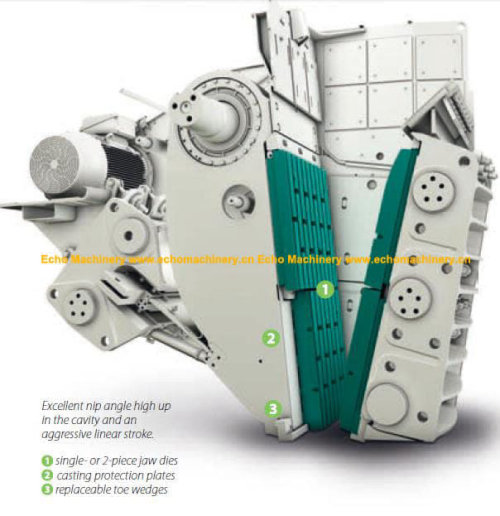

Tooth roller crusher feature 1) new design, small in size, large crusher teeth free download crusher teeth free download. As a professional crushing and grinding equipments manufacturer, The unique design of teeth and jaw allows the crusher crusher teeth 4140 - crushing and grinding plant solutions

Learn MoreSource The Ideal Wholesale roller crusher design

Choosing a roller crusher design is made easier by the filters and search engine at Alibaba's catalog. Check that the crusher you want has enough compressive power to handle solid rock,

Learn MoreThe Influence of the Structure of Double Toothed ... - IOPscience

The best test scheme and the order of three influencing factors are obtained, which provides the basis for the design of the double toothed roller crusher.

Learn Moreroller crusher design in south video - Henan Technox Mining

Crushing roller. 6 diax 6. 5 . cane crushing capacity. 750 1000 kgshr. we export type 1 heavy duty sugarcane crusher with all standard accessories to operate the machine easily. our type 2 sugar cane crushers is 3 rollers, double roller, and horizontal sugar cane crusher. they can be operated using electric motor or diesel engine.

Learn MoreRoller crusher - lts.company

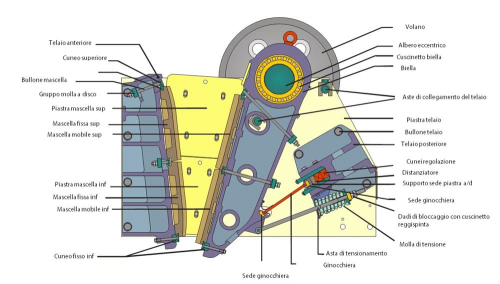

By design, roll crushers are one-, two- and four-rollers. Four-roller crusher can be seen as two two-roll mills, mounted in the same body, because one pair of rollers is located above the other one. Grinding principle of any roll crusher is based on abrasion and compression, shear and crush of material supplied into the crushing chamber top.

Learn MoreRoll Crusher Design Calculations

the processing system of the double-toothed roller crusher makes it possible to crush any type of raw material from hard (limestone and rock) to soft (clay, soil and mud) or even elastic-like wood or rubber tyres. the rotation speed, especially if compared to traditional crushers, is very low; so low, in fact, that tip speed is under 3 m/s.

Learn MoreThe special roller crusher design

Double roller crusher is made of two crushing rollers. While the two rollers are designed in different working ways: one is fixed, the other is active. But why? The fixed roller is designed to ensure the discharging size. This fixed roller, usually (or feed in metal piece) this roller stands firmly, then it will not only ensures the machine performance, but also ensures the discharging size.

Learn Moreindustry double tooth roller crusher design - News

Introduction of toothed roller Crusher: The Toothed Roll Crusher is suitable to the industries of coal, metallurgy, mineral, chemical and

Learn More