sandvik cone crusher manual pdf

CH440 Cone Crusher With A Robust Crusher Design — SRP

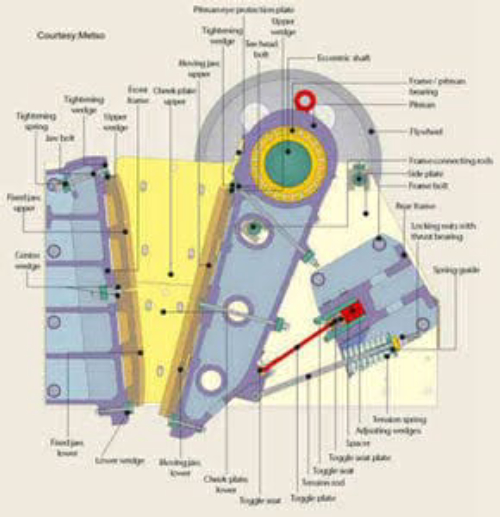

CH440 is suitable for a high-capacity secondary application or a high-reduction tertiary or pebble-crushing application, and it can be matched to changes in production through the selection of crushing chambers and an eccentric throw. This flexibility means that it's suitable for a wide range of applications.

Learn MorePDF Cone Crushers A4 juni - Inter MineralPDF

The hydraulically adjusted CS & CH cone crushers manu- factured by are characterized by robust design and high performance. In combination with the CLP crushing chambers, high motor powers give these crushers capacities which are in most cases comparable with those of other, larger crushers.

Learn MoreCone Crusher Manual - [PDF Document

qh 33 0 Operatorâs manual serial number Original Instructions QH330 © Copyright Sandvik. All rights reserved. No parts of this document may

Learn MoreCone Crushers | Inter Mineral

cone crushers are an excellent choice as secondary crushers in combination with a jaw or a primary gyratory crusher or in the third or fourth crushing

Learn MorePDF CH890i & CH895i CONNECTED CONE CRUSHERPDF

general design criteria ch890i ch895i crusher type cone crusher, hydraulically adjusted application minerals processing crushing stage secondary tertiary, quartenary, pebble max. feed size, f100 428 mm 127 mm css range 13-70 mm 10-70 mm nominal capacity* 275-1,837 mtph 258-1,077 mtph ambient temperature -20°c to +40°c (contact if outside

Learn MorePDF CH870 CONE CRUSHER - Mining and Rock TechnologyPDF

general design criteria ch870 crusher type cone crusher, hydraulically adjusted application minerals processing crushing stage secondary, tertiary, quartenary, pebble max. feed size 300 mm css range 10-70 mm nominal capacity* 179-1,473 mtph ambient temperature -20°c to +40°c (contact if outside range) altitude of site ≤ 2000 m (contact

Learn MoreCH430 Cone Crusher Suitable For Secondary Applications

CH430 Stationary Cone crusher is designed to meet the needs of modern day crushing, and its excellent versatility and adjustable throw give you the possibility to fine tune and optimise your performance and overall output. If you need any advice regarding product selection or technical support, please contact a member of our team.

Learn MoreCrushing Plant--Hydraulic Cone Crusher

2010. 7. 12. · vibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc. The designed capacity is from 40t/h to 600t/h. To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plant.

Learn MoreCH430 Cone crusher - Mining and Rock Technology

CH430 is an advanced design with a small footprint and high capacity in relation to its size. This cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. Email us Request a quote.

Learn MorePDF MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE - Mining and ...PDF

CRUSHER SELECTION QUICK GUIDE 1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm. 4.

Learn MoreMASTER YOUR OUTPUT CRUSHER SELECTION QUICK

Secondary Cone Crushers S-type B G Secondary HSI Impact Crushers P B P G G P Cone Crushers H-type B G G P B G P G Manual calibration Automatic calibration Lost production TIME

Learn More