jaw crusher eccentric shaft design

B10 ECCENTRIC SHAFT jaw crusher eccentric shaft design

B10 ECCENTRIC SHAFT jaw crusher eccentric shaft design CN102561854A - Adjustable latch hook mechanism. Said adjustable bearing pin is an eccentric shaft. of Regulation sketch map that the present invention regulates pin 4 and adjustment cam A5, B10. GoTo Products | Bosch Rexroth USA. 4WEH16HD7X/O6EG24N9ETK4/B10.

Learn MoreCONCEPTUAL DESIGN FOR A PROTOTYPE FUEL

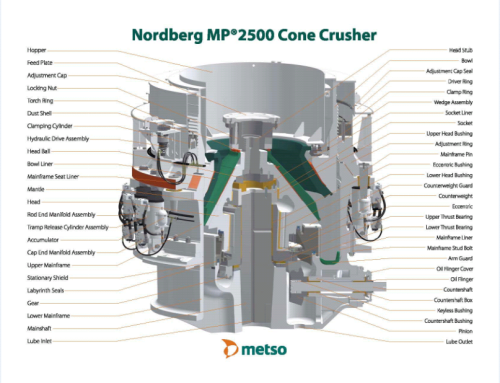

The first major equipment item is an overhead eccentric jaw crusher. (primary crusher) designed for initial crushing of the entire HTGR fuel.

Learn Moreeccentric shaft design in jaw crusher

The Eccentric Shaft of Jaw Crusher Jul 29 2014. The eccentric shaft of jaw crusher is used to transmit torque and make the equipment rotating in jaw crusher. So it should not only bear bending load but also transfer torque in operating. There is a strictly requirement to the material and design of the eccentric shaft. I will answer this

Learn MoreROC Jaw Crusher

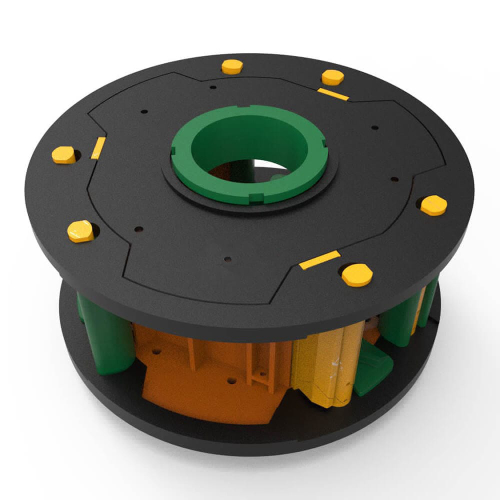

ROC jaw crushers work by applying a compressive force exerted as the connecting rod moves forward and backward. The rod is attached at the top to an eccentric

Learn MoreDesign Of Eccentric Shaft For Jaw Crusher Sample Steel Mill Project Report

The Design Of Rolling Bearing Mountings Schaeffler. 92 Double toggle jaw crusher Double toggle jaw crushers have a large mouth opening They are used for example as primary crushers to prepare ballast for road building The coarse crushing is followed by further crushing operations until an aggregate of the size and shape required eg gravel or grit is obtained Operating data Input power

Learn MoreEccentric Eccentric Shaft Of A Jaw Crusher-jaw Crusher

Industrial Solutions Jaw Crushers. Average throughput rate of singletoggle jaw crusher standard version tolerance 10 doubletoggle jaw crushers design doubletoggle jaw crushers are equipped with a doubletoggle system which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft causing the toggle plates to alternately flex and

Learn MorePDF "Computer Aided Design of Jaw crusher"PDF

The movable jaw is pivoted at the bottom and connected to an eccentric shaft. The universal crushers are pivoted in the middle so that the jaw can swing at the top and the bottom as well. Maximum amplitude of motion is obtained at the top of the crushing plates. Dodge type crushers are not used for heavy duty and commonly found in laboratories.

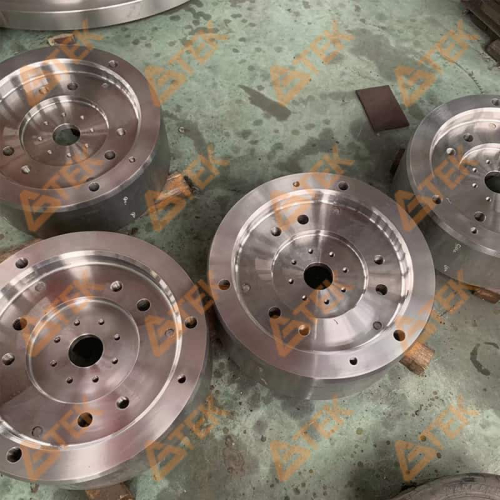

Learn MoreEccentric Shaft For Jaw Crusher - Precision Machine Shop

Eccentric Shaft For Jaw Crusher. December 26, 2018By: Molly Risak. No Comments. No comments yet. Sorry, the comment form is closed at this time.

Learn MoreDesign Of Eccentric Shaft For Jaw Crusher

The single-toggle crusher is also known as an overhead eccentric for its eccentric shaft is up above compared to the Dodge which has its shaft below/under Here the eccentric is integrated into the "sAug 14 · The jaw crusher's moving jaw undergoes two main types of motion one resulting from the eccentric shaft movement and the second from the toggle plate and the

Learn MorePerformance optimization of jaw-type rock crushing machine

Current jaw-type crushing machines are designed a optimization of jaw-type rock crushing machine through shaft eccentricity redesign.

Learn MoreJaw Crusher - Balaji Engineering Works

The provision for grease lubrication system is made on the top of pitman. ECCENTRIC SHAFT : The eccentric shaft is machined out of special steel and due

Learn More