double roll crusher working principle

Things You Should NEVER Do While Operating Double Roll

Smooth double roller crusher Usage and features and working principle. Today double roller crusher is utilized for crushing ore, coal, cement, glass, silicate

Learn MoreDouble Roll Crusher Design Principles

Roll Crusher Construction Operating Principle. Local Rule 47.5 provides The publication of opinions that have no on the basis of wellsettled principles of law imposes needless expense on the public Twin Roll Crusher which it sold to Mallette Brothers in 1974.The Roll Crusher was the crushers control mechanism was constructed adjacent to the roll crusher.The crusher began operation in late 1974

Learn MorePrinciple Of Roll Crusher

Jul 30, Double roller crusher working principle. The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve

Learn MoreRoll Crusher Working Principle

Roll crusher working principle roll crushers, or crushing rolls, or double roller crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. they still haveseful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum, phosphate.

Learn MoreWhat's a Double-Roller Crusher?

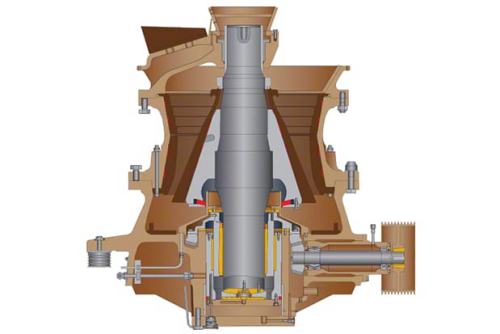

The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and

Learn MoreLab Double-roll Crusher

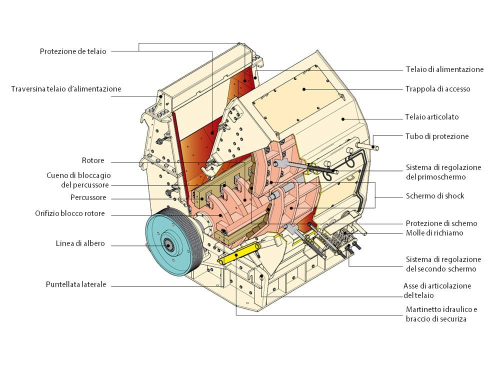

Working Principle 1.Roll crusher mainly consists of rollers, roller support bearings, pressed and regulation devices, drives, and etc. 2.Adjusting of output granularity: there is a wedge or gasket adjusting device between the two rollers. Wedge adjusting device:there is a adjusting bolt on the top of the Wedge device.

Learn MorePrinciple Of Double Roller Crusher

Double roller crusher working principle The mode of operation of roll crushers is extremely simple the standard spring rolls consisting of two horizontal cylinders which revolve towards each other The set is determined by shims which cause the springloaded roll to be held back from the solidly mounted roll.

Learn MoreRoll Crusher Brochure | PDF | Transmission (Mechanics) | Bearing

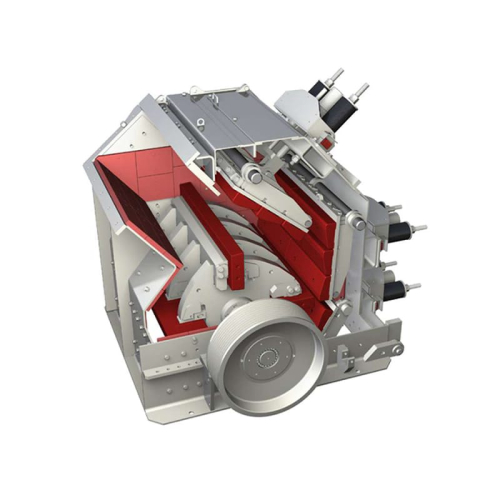

Roll Crushers. For Uniform Crushing And Sizing With Less Fines, Its Gundlach. Single-Stage and Two-Stage Roll Crushers 2000, 3000, 4000 and 5000 Series Every day, Gundlach crushers demonstrate their proven superiority by producing high product uniformity with less fines, resulting in Lower operating and maintenance costs More saleable and profitable crushed

Learn MoreDouble Roll Crusher Principle

Working principle of double roll crusher a roll crusher crushes using compression with two rolls rotating about a shaft towards the gap between the rolls the gap between the rolls is set to the size of product desired with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn MoreRoll Crusher - Mineral Processing

Working principle. When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected

Learn Moreroller crusher working principle stone crusher machine

Double roller crusher is equipped with two crushing rollers The distance between two rollers can be adjusted According to the particle size required by the user

Learn More