crusher selection guide

PDF R Crusher Wear Parts Reference GuidePDF

Blow Bar Selection & Application Guide • Blow Bar Part Codes. 5 18% MANGANESE Standard fit on all Jaw & Cone crushers. A good all round liner for all applications. The hardness of a material is a major consideration in the selection of the type of crusher to use. Hardness is a factor in the amount of wear and tear crushers and screens

Learn MoreCrushers Selection Guide: Types, Features, Applications - GlobalSpec

Cone crushers. Medium hard to very hard. Abrasive. Dry or wet, not sticky. 3/1 to 5/1. Quarried materials, Sand & gravel. Gyratory crushers. Soft to very hard. Abrasive. Dry to slightly wet, not sticky. 4/1 to 7/1. Heavy mining, Quarried materials. Horizontal shaft impactors. Soft to medium hard. Slightly abrasive. Dry or wet, not sticky. 10/1 to 25/1

Learn MoreHorizontal Shaft Impact Crusher Materials Guide | CMS Cepcor

Manganese Steel Manganese hammers and blow bars are commonly used primary crusher applications and provide high shock resistance and are available in both Mn14% and Mn18% material grades as well as our special MNX50 grade. They are well suited to applications where tramp iron is possible in the feed material.

Learn MorePDF Handbook of Crushing - TerraSource GlobalPDF

process of selecting and sizing a crusher to a series of formulas. The selection process is largely based on experience and testing — experience with actual field applications and laboratory tests that show how a given material will be reduced by a given crusher type. The main purpose of this handbook is to explain the

Learn MoreSelection Chart Crusher - HN droled mine treatment equipment expert

Model Selection Guide for Wireless Charging Module. SELECTION GUIDE DFRobot. 30.04.2021. MP3 Module Selection Guide. SELECTION GUIDE Arduino. 30.03.2021. Dec 07, The Skull Crushers Hypertrophy Guide. Skull crushers are one of the best exercises for building bigger triceps, and they're quite good for increasing bench press strength

Learn MoreCrushers Selection Guide

May 21, Crusher Selection. While crushing is governed by basic laws of physics, no single law or rule take the place of experience and testing in the selection and sizing of a suitable crusher for a given application. A number of factors go into the proper selection of a crusher for a given application including th following.

Learn MoreSelecting the Right Crushing Equipment | Agg-Net

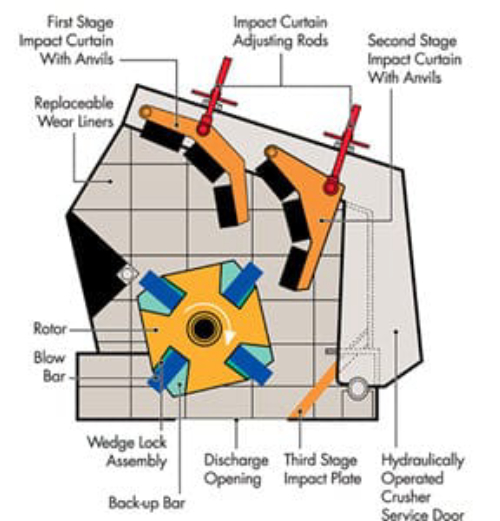

Most crushers used for aggregate production fall into one of three main categories/types: Compressive crushers – which squeeze the material until it breaks. Impact crushers – which

Learn MoreHow To Choose Cement Crusher? | Jaw Crusher, Cone

10/30 · AGICO Cement is a cement equipment manufacturer, we supplies jaw crusher, cone crusher, impact crusher, hammer crusher and other cement manufacturing machines,

Learn MoreCement Crusher Selection Guide-CHAENG

Cement Crusher Selection Guide-CHAENG. 2020-05-29 10:03:58. Share to: PDF Download. The cement crusher is the necessary equipment in the cement production line. with the wide application of cement and higher requirement for the cement manufacturing process, the cement crusher gets more and more hot in the cement industry.

Learn MoreCrusher Wear Parts Selection Guide

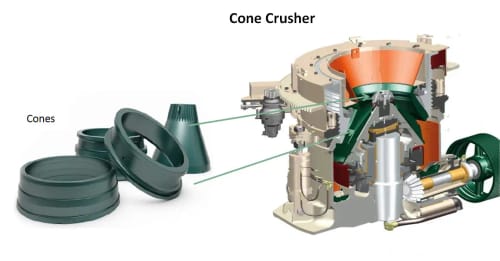

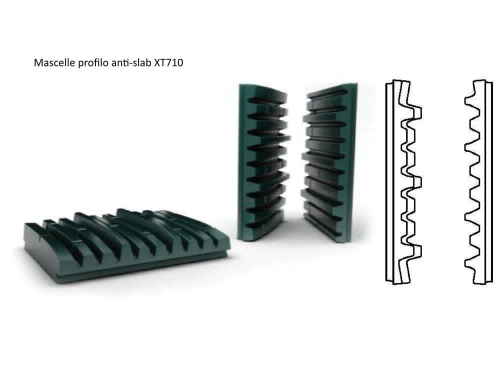

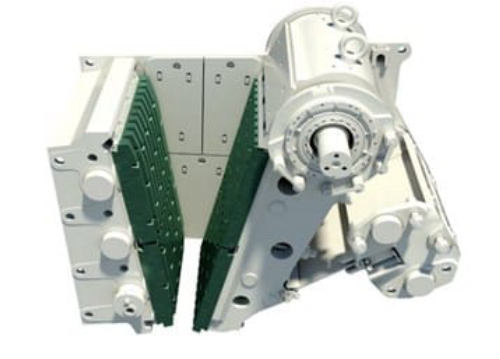

Crusher Wear Parts Selection Guide JAWS, CONES & IMPACTORS CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Parts Materials in Properties Manganese Wear Mechanisms in Crushing Chamber Wear Factors Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS

Learn MoreCrusher Wear Parts Selection Guide - Qiming Machinery

There are three types of crusher wear parts: Jaw crusher wear parts Cone crusher wear parts Impact crusher wear parts

Learn More