tubing hanger installation procedure

tu hanger | Energy Glossary - Schlumberger

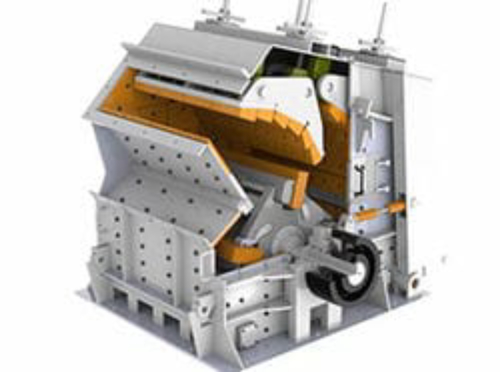

tu hanger. 1. n. [Well Completions] A device attached to the topmost tu joint in the wellhead to support the tu string. The tu hanger typically is located in the tu head, with both components incorporating a sealing system to ensure that the tu conduit and annulus are hydraulically isolated. Wellhead components.

Learn MoreWellhead Installation - Stream-Flo

Slip-Loc casing heads. Full bore drilling systems. Mandrel casing hangers in a variety of materials and thread combinations. Secondary seal assemblies from metal sealing to elastomeric. Tu hangers from single to triple string are available in different materials and thread combinations. Gate valves from 2 1/16-2000 psi to 7 1/16-15000 psi

Learn MoreFMC Tu Hanger

BACK PRESSURE VALVE : TO INSTALL BPV, ATTATCH BPV WITH R/I TOOL BY A BRASS PIN AND RUN IN THE ASSEMBLY WITH STEM JAR. PLACE IT IN THE TU HANGER AND JAR DOWN

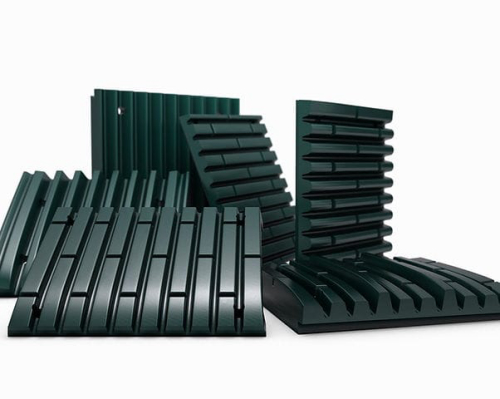

Learn MoreDifferent Types of Pipe Support Clamps & Hangers

Let’s see the below list of different pipe support clamps: 1. Yoke-Type Pipe Clamp. Yoke-type pipe clamps are required for the suspension of high-temperature horizontal stationary insulated lines. This type of clamp is recommended for 4″ – 6″ insulated lines. 2.

Learn Morewell completion equipment part - 7 tu hanger

Apr 29, · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreSpecification for Installation Method Statement of Pipe

5 rows · Where pipe exceeds maximum loading recommended for clevis type hangers, furnish steel pipe

Learn MoreAn Installer's Pocket Guide for Swagelok® Tube Fittings (MS

Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight. High-pressure applications and high safety-factor systems: Further tighten the nut until the tube will not turn by hand or move axially in the fitting. Mark the nut at the 6 o’clock position. Swagelok Tube Fittings Up to 1 in ./25 mm

Learn MorePDF An Installer's Pocket Guide for Swagelok® Tube Fittings (MS-13-151;rev ...PDF

Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight. High-pressure applications and high safety-factor systems: Further tighten the nut until the tube will not turn by hand or move axially in the fitting. Mark the nut at the 6 o'clock position. Swagelok Tube Fittings Up to 1 in ./25 mm

Learn MoreApplication of Subsea Tree in Deep Water

the assembly procedures and the assembly drawings. Design procedures are shown in. Figure 1.8. •Tu hanger system. Hanger. •A tree connector to attach

Learn MoreWorkover programme - tu change out

8.6.3 Install a new 7" nominal DT seal in the tu hanger neck. Lightly coat the seal sub with anti-scuffing paste and also apply the lubricant to the GS seals and the tu hanger extended neck. 8.6.4 Pick up the tu bonnet by means of the two lifting eyes provided and carefully lower it over the tu hanger neck.

Learn More