spiral bevel gear vs hypoid

Expect Increased Efficiency With Hypoid Gearing Instead Of Worm Gearing

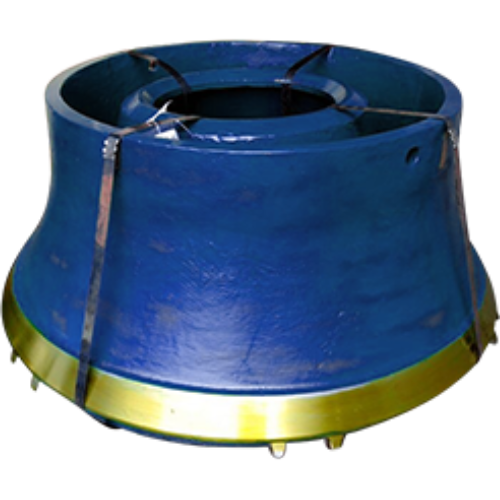

The shape of a hypoid gear is hyperbolic; the shape of a spiral bevel gear is normally conical. A hypoid gear has a 25:1 ratio range. A hypoid gear set, in this ratio range, is approximately 90% efficient per stage. Worm gears (Figure 4) consist of a non-intersecting shaft with a spiral thread that engages with and drives a toothed wheel.

Learn MoreHigh on Hypoids | Electronic Design

In addition, hypoid gears tend to run smoother and quieter than spiral bevel gears. According to Dudley's, efficiency of a hypoid gear (90

Learn MoreWhat is the difference between helical, spiral and hypoid gear?

Helical gear: In a helical gear, the edges of the gear teeth are not parallel to the axis of rotation, but are set at an angle. · Spiral gear: A spiral bevel

Learn MoreCustom - spiral-gears

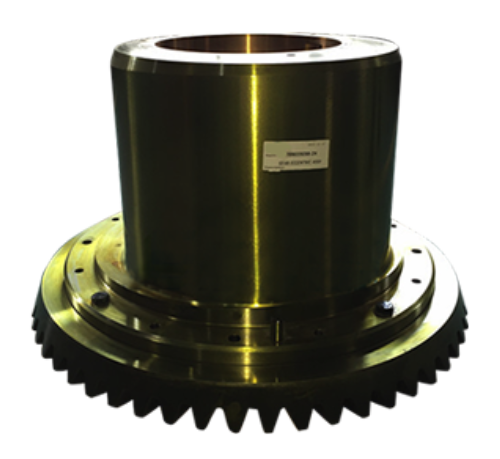

Hypoid bevel gears. In automotive use, hypoid bevel gears are utilized in the differential, which permits the wheels to rotate at different speeds even though sustaining the vehicle's dealing with. This gearbox assembly is made up of a ring gear and pinion mounted on a provider with other bevel gears.

Learn MoreSpiral Bevel and Hypoid Gear Cutting Technology Update

introduced. Today, gears are made on high-production, automated machines with direct drives and precision cutting tools. Face Mill (Single Index) and Face Hob (Continuous Index). There

Learn MoreStraight Bevel Gears vs. Spiral Bevel Gears - True Gear

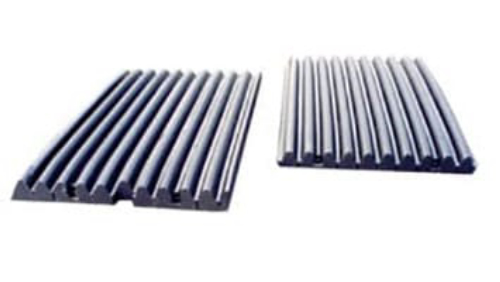

Oct 30, · As the name suggests, a straight bevel gear has straight teeth like a spur gear that are cut along the axis on a cone. For this reason, it can be quite noisy as the teeth of the mating gears collide upon making contact. On the other hand, a spiral bevel gear has spiral teeth that are cut in a spiral curve across the pitch cone.

Learn MoreDifference Between Straight Bevel Gear and Spiral Bevel Gear

Here teeth have a spiral profile and thus gradually come in contact during mating. Thus it offers smooth, vibration-free and quiet operation.

Learn MoreComparison of hypoid, helical bevel and worm gear motors

Our experience shows that the average efficiency of a hypoid gear unit is 88% with two stages and 83% with three stages. The efficiency of a helical bevel gear

Learn MorePDF Gear Mathematics for Bevel & Hypoid Gears - Gear TechnologyPDF

At the beginning of this chapter the development of a face-milled, conjugate spiral bevel gearset is conducted. Next, an ana-logue face-hobbed bevel gearset is derived that in a third step is converted to a non-generated (Formate) version. In step four an offset is added to the Formate spiral bevel gearset that results in a hypoid gearset.

Learn MoreOEM - helical-bevel-gear

The Hypoid bevel equipment is comparable to the spiral bevel equipment but differs in the condition of the enamel and pinion. The smallest ratio would outcome in the cheapest gear reduction. A Hypoid bevel equipment is quite resilient and productive. It can be utilized in confined areas and weighs much less than an equal cylindrical equipment.

Learn MoreHypoid bevel gear VS spiral bevel gear

Spiral bevel gears and hypoid bevel gears are the main transmission methods used in automobile final reducers.

Learn More