single roll crusher working principle

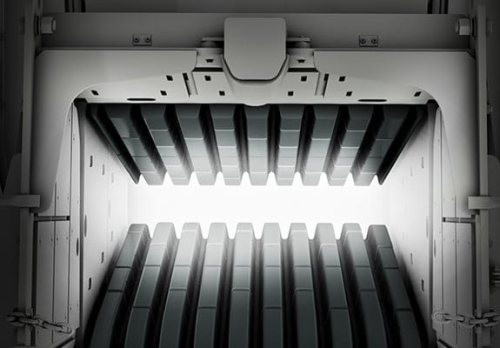

What's a Double-Roller Crusher?

The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and

Learn Moretypes of crusher machine portable rock crusher socket liner manual pdf

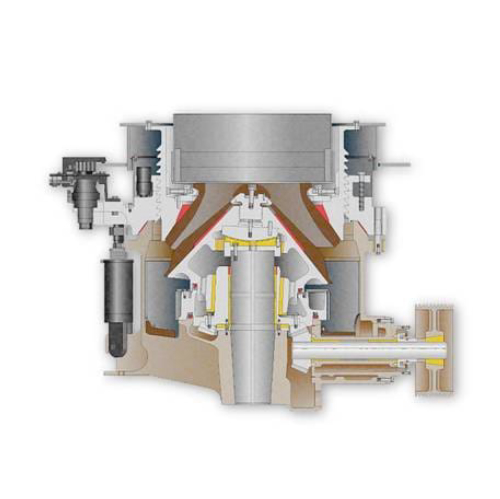

There are four traditional types of crushers in materials engineering. They are known as jaw crushers, gyratory crushers, cone crushers and roll crushers. Types Of Crusher - Working Principles of Crushers. Based on the working principle, crushing machines are divided into the following types: Cone crusher; Jaw crusher; Impact crusher.

Learn MoreSingle Roll Crusher Working Principle In Lesotho

A required crushing process may consist of just one rotor crusher a combination of two rotor crushers a combination of one rotor and one roll crusher or just one roll crusher rotor crushers can treat quite coarse material with maximum inlet size of some 300 300 mm as the typical crushing ratio is 10 at a single stage the material can be.

Learn MoreDual roll crushers, how they function - Mine Engineer.Com

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn MoreRoll Crusher Working Principle

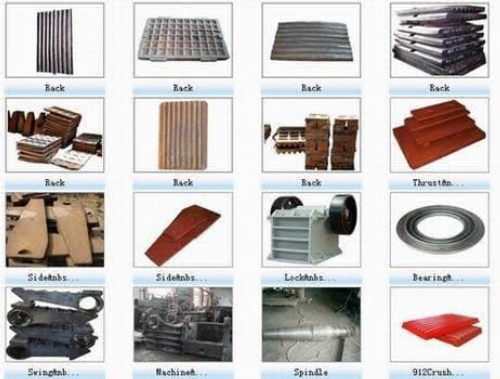

Single Roll Crushers Mineral Processing Metallurgy. Metallurgical ContentRoll Crushing Action and Working PrincipleDischarge Product of a Roll CrusherOptimal Roll Crusher Feed SizeRoll Crusher CapacityApplications: When to use a Roll Crusher On the right, a Roll Crushers is shown in a sectional elevation o . View Details Send Enquiry Working Principle Of Smooth

Learn MoreSingle Roll Crusher Working Principle-roller Crusher

the single-toothed roller crusher actually combines the jaw crusher and part of the single roll crusher working principle grinding mill equipmentsingle roll Roll Crusher Working Principle Of. roll crusher working principle henan deya. 2012-7-30 double roller crusher working principle. the mode of operation of roll crushers is extremely simple, the

Learn MoreSmooth Roll Crusher - J.C Steele & Sons

The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsum waste.

Learn MoreRoll crushers - SlideShare

ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone. The particles are drawn into the gap between the rolls by

Learn MoreRoll crusher working principle & structure

The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on

Learn MoreSingle Roll Crusher Working Principle

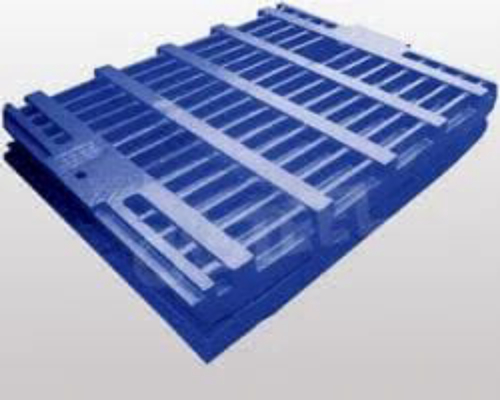

Roll Crushers. A Roll Crusher is massively built; without gears, countershafts, or oil pumps, and with only one moving part. A heavy, annealed, cast steel frame supports the unusually large,

Learn MoreStructure And Principle Of Single Roll Crusher

Roll Crusher With stable Performance Fote Machinery. 2021830ensp enspWorking principle of roll crusher The main working parts of the roller crusher is the cylindrical rollers The rollers are supported by the fixed and movable bearings and they are relatively rotating which are driven by the motor. Single Roll Crusher Market Size Share Research

Learn More