reduction ratio of jaw crusher

Reduction Reduction Ratio Calculation Jaw Crusher From Ethiopia

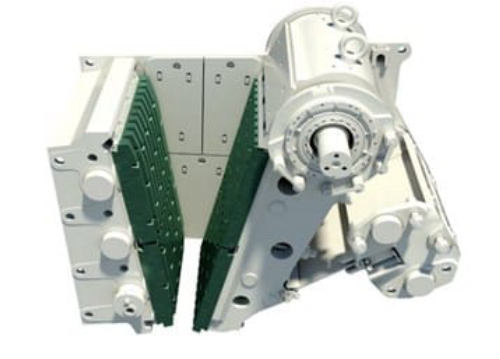

May 15, 36 FACTORS INFLUENCING THE OPERATION OF A BLAKE JAW CRUSHER. 1. The reduction ratio ( Gape / Set) 2. Speed and amplitude of strokes and movable jaw. 3. Size distribution of feed. 4. Crushing properties of ore. CAPACITY OF A JAW CRUSHER T ( Tones/ hr) = 3.75 LS. L- Length of feed opening ( cm).

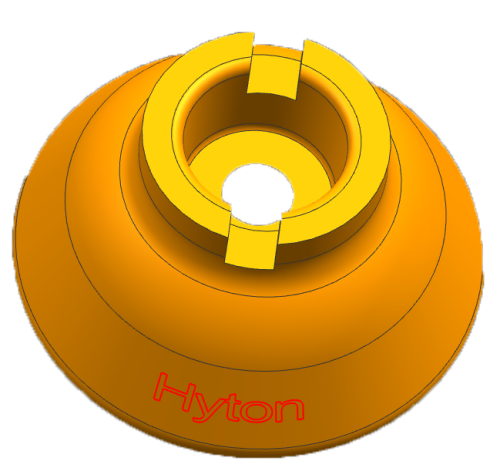

Learn MoreReduction ratio of Cone crusher,impact breaker,roll crusher,Jaw crusher

Reduction ratio is 20 to 1. Reduction ratio of Jaw crusher A crusher that breaks material by squeezing or compressing it between two jaw plates, one moveable and one stationary. Normally used as a primary crusher. Uses compression and some attrition to crush material. Reduction ratio is 6 to 1. Reduction ratio of Vertical shaft impactor

Learn MorePDF) SIZE REDUCTION BY CRUSHING METHODS

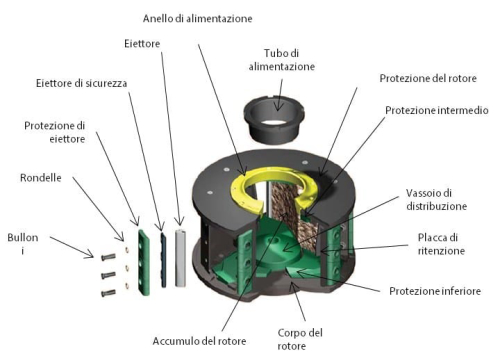

2. All crushers have a limited reduction ratio meaning that size reduction will take place in stages. · The operating stages in minerals process

Learn MoreJiangtai Large Reduction Ratio Pto Jaw Crusher,Pto Stone

JIANGTAI Large Reduction Ratio PTO Jaw Crusher, PTO Stone Crusher For Sale ; Mobile Function: Optional ; Rotor Diameter: 400-1800mm ; Shaft Material: 45# Steel.

Learn MoreThe Reduction Ratio Of A Jaw Crusher

Jaw crushers offer reduction ratios of up to about 61, while cone crushers can reduce material size up to a maximum of 81 ratio. The finer the crushing, the smaller the reduction ratio. As a basic rule, jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher can accept.

Learn MoreTECHNICAL NOTES 5 CRUSHERS - Mineral Tech

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side set (OSS) is specified. This reflects the fact that considerable

Learn MoreIntroduction to Rock Crushers - ELRUS Aggregate Systems

Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio. The finer the crushing, the smaller the reduction ratio.

Learn More5″ x 7″ High Reduction Ratio Jaw Crusher - 911Metallurgist

5″ x 7″ High Reduction Ratio Jaw Crusher The 911MPE-TM-T is a Jaw Crushers for Coarse Primary Crushing and Mid Range Primary Crushing. This jaw crusher is equipped with a standard 5 HP motor and a 5″ X 7″ jaw cavity that will produce a discharge crushed product of under <1mm. Well-proven single toggle, high reduction Jaw Crushers.

Learn MoreTips to maximize crushing efficiency - Pit & Quarry

May 13, · Ideally, the reduction ratio of a jaw crusher should be 6-to-1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor. The reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percent.

Learn MoreWhat Type of Crusher Is Best for Primary Crushing?

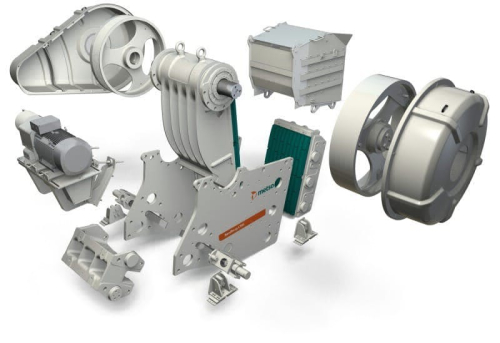

These types of impact crushers can handle slightly abrasive, dry or wet material that is not sticky. They provide a reduction ratio of 10:1 to

Learn MoreRock Crusher with a High Reduction Ratio - RUBBLE MASTER

Exceptional Reduction Ratio Up to 30% Fines after 1 Pass Lowest Operating Costs The RM V550GO! can replace a traditional jaw cone, and screening plant setup. Like all RUBBLE MASTER impactors it features all the benefits that make it easy and safe to operate. One-Man Operation Your loader operator controls the crusher conveniently from his cab.

Learn More