lip seal gasket design

PDF Seal Design Guide - Apple RubberPDF

Throughout this guide, the o-ring is used as an example in our discussion of seal design principles. We have made this choice for these reasons: 1. It is the most common and most widely known type of seal in use today. 2. It is used in all types of applications and by a broad range of industries. 3.

Learn MoreWeld Ring Gasket - Spetech

SPETECH® has been in the industrial sealing systems for 30 years. Through all this time we've been collecting experience and supplying our products to 100

Learn MoreGASKET DESIGN & BOLTING

2018. 4. 4. · Kammpro Gasket Features Advantages: Soft sealing faces Flexible graphite facing material Serrated metal core Wide range of metal cores Sizing to accommodate application Minimum Gasket Stress: Lower M & Y factors M = 2.75 Y = 3,700 PSI = 3700 PSI (Minimum Stress) Core can handle a maximum stress of 60,000 PSI

Learn MorePDF PTFE Lip Seal Design Guide - MacrosealPDF

The FlexiCase seal is a metal-cased rotary lip seal suitable for applications where elastomeric lip seals fail and mechanical seals are too costly. The filled PTFE element provides greater chemical compatibility, wider temperature ranges, higher pressure capabilities, and longer life than elastomeric lip seals. ** Elgiloy® is a registered mark

Learn MorePDF PTFE Lip Seal Design Guide - repurvis.comPDF

The FlexiCase seal is a metal-cased rotary lip seal suitable for applications where elastomeric lip seals fail and mechanical seals are too costly. The filled PTFE element provides greater chemical compatibility, wider temperature ranges, higher pressure capabilities, and longer life than elastomeric lip seals. ** Elgiloy® is a registered mark

Learn MoreM Seals frontpage

Additionally, kits can be custom labeled, as well as have an accompanying chart designed to match o-ring sizes exactly. Read more. Industries. Oil & Gas.

Learn MoreLip seals - Gaskets to drawing, rubber's sealing parts ... - Rezingom

Lip seals may be considered as a special type of precision gasket. They are available in different shape of the cross section, as for instance with single lip, with double lips, with symmetric or asymmetric shape, rod seals, piston seals, scrape seals and reach their sealing function by rotation or by an axial movement.

Learn MoreGasket Design Guide: Five Things You Need to Know - Elastoproxy

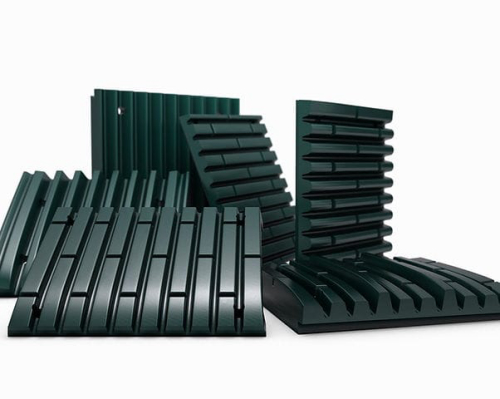

Rubber profiles for gaskets come in a variety of shapes. Four of the most common types are D, P, E, and lip seals. D-seals have a half-moon bulb that provides sealing under pressure and a flat, straight section that attaches with an adhesive such as PSA tape. P-seals have a rounded bulb and a flat stem. The bulb provides sealing under compression.

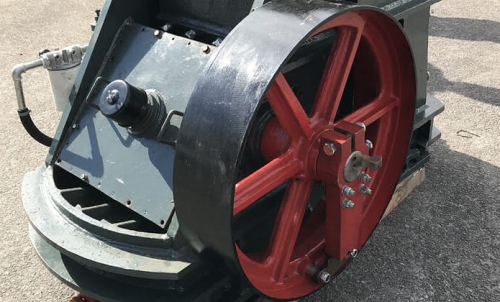

Learn MoreRotary Lip Seals, Oil Seals - Eriks USA

Advantages: Secure sealing on unpaved and stainless steel shafts. No traces of damage on the surface. No need for treatment of the shaft surface (coat, temper, nitrate,), nor the use of extra sleeves. Thanks to the tangential and radial tension on the lip seal, no pump effect is provided. Low friction coefficient, low friction losses. Longer

Learn MoreEngineered Lip Seals | CTG Inc

C.T. Gasket & Polymer Co. has over 100 years of engineering expertise with the highest quality Engineered Lip Seals and other products. CTG is your source for Engineered Lip Seals. Call. CALL US 800.299.1685. For your custom Engineered Lip Seals design, or reverse engineering, our exemplary service and efficient production ensures prompt

Learn MoreOil Seals | Seal & Design, Inc | Manufacturer and Distributor

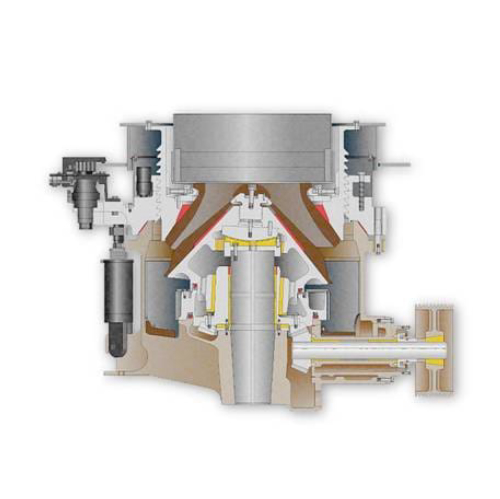

An oil seal normally consists of three basic components: the rubber sealing element, the metal insert (case) and the garter spring. The purpose of the sealing

Learn More