hydrogen check valve

Instrumentation Solutions for Hydrogen Applications

The Parker Autoclave Engineers O-Ring Check Valves CXO Series (HYG option) can withstand temperatures ranging between -73°C and 316°C and pressures up to 1,380 bar (20,000 psi). Parker Bestobell’s valves are suitable for liquid hydrogen applications requiring temperatures as low as -253°C. All valves are pressure-tested prior to dispatch.

Learn MoreHYDROGEN - Valve and Flow Control Specialists

Hydrogen tube fittings and valves by DK-Lok, Hydrogen gas pipeline injection systems for Industry and transportation sectors. The ability to harness Hydrogen gives us sustainable energy strategy for our future. It is the most abundant chemical substance in the universe and from an energy perspective offers great benefits.

Learn MoreHigh Pressure Gaseous Hydrogen Check Valve

Longtime field-proven hydrogen check valve for various applications. Operating pressure is adjustable and ranges from 1379 bar to 4137 bar.

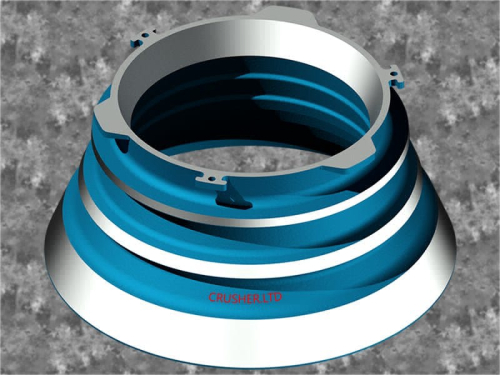

Learn MoreCone Check Hydrogen Valve

Realiable cone check hydrogen valve with compatible soft sealing system for hydrogen applications. With a 4M to 16M connection, medium pressure applications up to 22,500 psi (1.550 bar) are possible. It has a improved spring guide to improve the performance. It can be operated up to the pressure of 1550 bar.

Learn MoreHydrogen Flashback Arrestor w/check valve, High Vol 116

Buy Oxy - Hydrogen Flashback Arrestor w/check valve, High Vol 116 Lt/m 1/4" Barb HHO: Check Valves - ✓ FREE DELIVERY possible on eligible

Learn MoreCE Certification Hydrogen Check Valve Manufacturers and Suppliers

Hydrogen Check Valve - China Factory, Suppliers, Manufacturers "Based on domestic market and expand overseas business" is our development strategy for Hydrogen Check Valve, 1/8 Npt Needle Valve, Gas Regulator Body, Electric Solenoid Valve, Check Valve For Compressed Air.

Learn MoreNon-Return Valves

High-quality gas non-return valves protect against dangerous gas backflow. gases such as oxygen, nitrogen, methane, hydrogen and compressed air.

Learn MoreValves for Hydrogen Service: Challenges in Materials Selection

09/03/2022 · A valve design in a hydrogen application requires two types of materials; metallic materials when dealing with high pressure and cryogenic temperatures, and non-metallic materials for overall static and dynamic sealing and seating. Hydrogen however, poses a unique challenge for the materials selection for valves.

Learn MoreVespel® Hydrogen Valves and Seals | DuPont Automotive

DuPont™ Vespel® hydrogen valve seals provide long life and perform in environments with pressures up to 100 MPa. Vehicels powered by fuel cell technology require hydrogen valves with dependable seals. Vespel®, with low hydrogen permeation, is the material of choice for: • Safety/shut-off valves • Pressure control valves • Purge/drain valves

Learn MoreWhat to Look for in Hydrogen Valves | Swagelok

Operating conditions for hydrogen fuel systems are inherently challenging. When specifying hydrogen valves, considerations must include: Pressures. To achieve desired density, H2 must

Learn MoreHYDROGEN VALVES - OMB - SALERI - The highest standards of quality

OMB has developed a full range of products such as a tank valve (OTV), fuel receptacle (HFR), check valve (HCR) and thermal safety valve (TPRD) for Hydrogen applications at 700 bar. The application target is the automotive field, especially passengers and heavy-duty vehicles.

Learn More