gyratory crushers sizes

PDF 2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing EngineerPDF

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn MoreGyratory Crusher In Dwg

Cg810 i gyratory crusher cg810 i gyratory crusher cg810i crusher is built to be robust reliable and efficient connected to my they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing all

Learn Moregyratory crusher main

Super Capacity NMS GC5065 Gyratory Crusher You Deserve It. Apr 02 This NMS gyratory crusher can meet all your requirements It has large capacity low energy consumption high crushing efficiency high reduction ratio The shell is made of special alloy cast steel the main shaft is made of high strength forged alloy steel and the liner has long service life

Learn Morejaw crusher and gyratory crusher | Henan Deya Machinery Co., Ltd

7/29 · A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is created by forcing the rock against the stationary plate. The opening at the bottom of the jaw plates is the crusher product size gap. The rocks remain in the jaws until it is small enough

Learn MoreGyratory Crusher. 시장 2022 최신 개발, 동향 및 수요, 크기, 공유, 성장, 동향 및 예측, 2028

글로벌 Gyratory Crusher. 시장 2022-2028 보고서는 수익, 거래량, 규모, 가치 및 이러한 귀중한 데이터를 다룹니다. Gyratory Crusher. 시장 보고서는 수많은 다른 시장 관련 기본 요소를 포함하는 체계적인 시장 조사 보고서를 통해 Gyratory Crusher. 시장의 기회에 대한

Learn MoreJaw Crusher Manufacturer | CITIC HIC

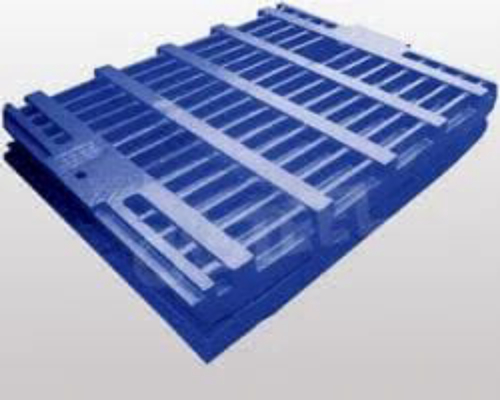

Gyratory Crusher; Jaw Crusher; Semi-mobile Gyratory Crushing Station Model, Feed opening, Max. feed size, Discharge opening, Crushing capacity

Learn MoreTypes of Crushers: What You Need to Know

After materials receive their first round of crushing, they are fed into a secondary crusher to be reduced further. Average material sizes range from 350mm to

Learn MoreGyratory Crusher-MECRU

The gyratory crusher has a huge output and is often used for coarse crushing operations of large enterprises or large production lines. It can crush the raw material ore produced by drilling and blasting to a suitable particle size for subsequent crushing process or beneficiation process. It is the key to the entire process.

Learn MoreSUPERIOR® gyratory crushers - Automation - PDF Catalogs

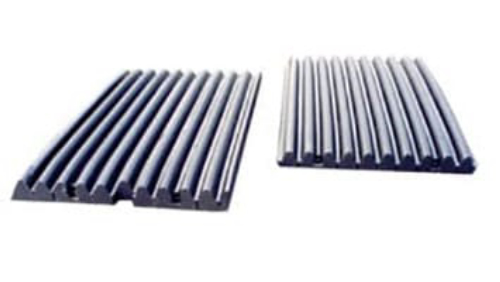

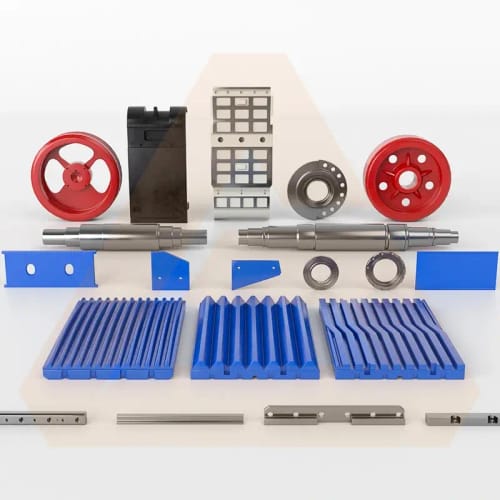

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 High-strength shell design, proven in the toughest applications, provides trouble-free operation and long life 3 Effective dust seal is equipped with an overpressure air

Learn More1 Crushing - Springer

Gyratory crushers-Typical installations. Crusher. Material. Product. Manufacturers. Plant and location size crushed hp size.

Learn MorePDF 2. Gyratory CrushersPDF

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn More