gear hobbing machine setting

Everything You Wanted to Know About Gear Hob

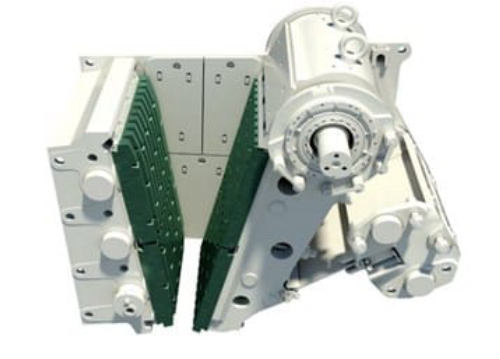

A hob machine has two skew spindles, one of which contains the blank, and the other of which contains the actual hob. The type of gear being produced dictates the angles at which these are held to one another. The machine is then set -up to rotate the two shafts at the proper ratio for whatever gear is being produced, while the hob

Learn MoreHob - Wikipedia

Hob machines are characterized by the largest module or pitch diameter it can generate. For example, a 10 in (250 mm) capacity machine can generate gears with a 10 in pitch diameter and usually a maximum of a 10 in face width. Most hob machines are vertical hobbers, meaning the blank is mounted vertically.

Learn MoreCNC Gear Hob Machine H200 by S&T Dynamics

H200, Machine Tools - Gear Cutting Machine, Korean Machine. CNC Gear Hob Machine. Model. H200 Faster and more precise hob setting. 자료 다운로드.

Learn MoreFast hob centering device for gear hob machine

fast hob centering device for a gear hob machine. The hob centering device consists of a column, a bracket, a tool setting rack, a tool setting rod,

Learn MoreGear Hob - Parts, Working, Diagram, Advantages

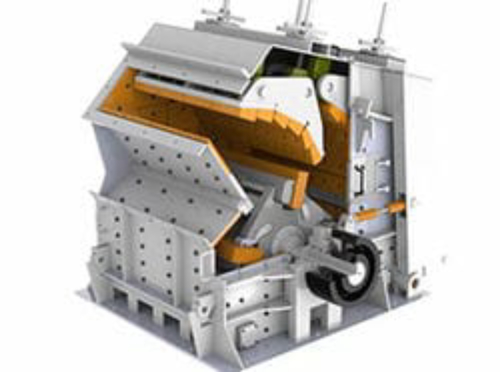

In hob spur gear the hob teeth are set parallel to the axis of rotation of the blank. For helical teeth bob , the axis of the hob is set over an angle to produce the proper helix. While worm gears are produced with the axis of the hob set the right angle to the gear blank. Generally two techniques are used in the hob process.

Learn MoreGear Hob Machine process - Overview - CNC Vertical Gear Hob

Hob machines provide gear manufacturers a fast and accurate method for cutting parts. This is because of the generating nature of this particular cutting process. Gear hob is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth.

Learn MoreWhat is Gear Hob (How is Gear Hob Done?) - Knords Learning

Gear hob is a method of making gear teeth by the help of a rotating cutter called a hob. By using gear hob operation, most of the involute gears are manufactured. Gear hob is a faster and continuous method of gear manufacturing, hence it shows high production rate in less time. Gear hob is used to manufacture spur gears, splines

Learn MoreThe Gear Hob Process - Gear Technology

The Gear HobbinglMachine Agear bobbillg machine consistsoffive common elements: • Awork spindle to rotate the work. • A hob spindle to rotate the hob. oA means of rotating the work spindle and hob spindle with a constant of ratio, depending on the number of teeth in the workpieceami the number of threads ill the hob.

Learn MoreGear Hob - Marples Gears

If a helical gear is to be cut, the hob axis is set at an inclination equal to the sum of the helix angle of the hob and the helix angle of the helical gear. The operation of gear hob involves feeding the revolving hob until it reaches the required depth of the gear tooth.

Learn MoreGear Hob Machine process – Overview

As the hob feeds across the face of the work piece at a fixed depth, gear teeth will gradually be generated by a series of cutting edges, each at a slightly

Learn MoreGear Hob Machine: Everything You need to Know about Gear Hob

The gear hob machine has two skew spindles, one of which has the gear blank while the other one has the hob. • The spindles are set at an angle from each other, depending on the type of teeth to be set on the gear blank. • The two spindle shafts are then rotated proportionally with the hob cuts on the gear blank.

Learn More