jaw crusher mounting

How to Properly Install and Use Jaw Crusher

Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and

Learn MorePDF Jaw Crushers JW Series - TerexPDF

these durable crushers utilize heavy duty components for optimum operation and long life. Typical applications for our single toggle jaw crushers are in mining, quarrying and recycling. The jaw is designed to crush in the most arduous applications with the hardest rock. Simple installation Adaptable mounting arrangement suitable for

Learn MoreJaw Crusher Working Principle – StudiousGuy

Advantages of a Jaw Crusher. 1. Jaw crushers are comparatively inexpensive. 2. Both the structure and working of a jaw crusher are quite simple. 3. The product size is quite small and can range up to millimetres. 4. Repair and maintenance of a jaw crusher are convenient and easy. 5. The reliability of a jaw crusher is significantly high. 6. The

Learn MoreC Series™ jaw crushers Proven reliability and

Mounting the crusher does not require anchor bolts. This is due to our unique solution where the crusher is standing on its own weight, and vibrations are absorbed by rubber dampers under support brackets. They are also engineered to deliver the maximum productivity at the lowest operating costs. Modular design enables easy installation Mining

Learn MoreC120™ jaw crusher - Outotec

Perfect fit for large-scale quarrying and mining applications · Top-level reliability · Superior performance · Safe to operate and maintain · Easy to install

Learn MorePDF midsize jaw crushers models 1021 Thru 3042PDF

per ton - that's the standard for jaw crushers. With 7 models ranging from the 1021 to the 3042 and a century of industry expertise, jaw crushers have proven themselves in the most difficult sand & gravel, quarried rock and recycling operations. The crusher main frame is the core element to success.

Learn MoreJaw crusher C120 - Thomasnet

The crusher is mounted without bolts between crusher and structure using mounting pads, which absorb the dynamic forces thus reducing the dynamic loads trans-.

Learn MoreJaw Crusher – Conmix Crusher

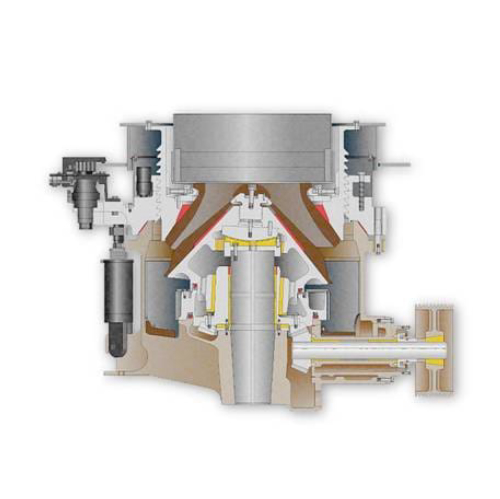

Jaw Crusher is consists of many parts, like eccentric draft, frame, large belt wheel mobile jaw crusher, flying wheel, toggle jaw plates, gap adjustment screw and so on. The main function of Jaw Crusher is to crush large rocks into smaller rocks, gravel, rock dust and gravel to satisfy different requirement for the products.

Learn MoreR1200D Track-Mounted Jaw Crusher

The mobile track mounted Jaw Crusher R1200D is based on a hydraulic concept and the ideal solution for any applications which demand highest requirements to

Learn MoreJaw Crusher Installation Points_The NIle Machinery Co.,Ltd

Jaw Crusher Installation Points. 1, equipment to lay the foundation. The jaw crusher is usually installed on a concrete foundation with a drain tank on the

Learn MoreJaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn More