welding manganese alloy

Welding Manganese Steel Plate - American Welding Society

2007/1/26 · Can anyone suggest a method and consumables for MIG welding AMS (11%-14% Manganese) steel plate? I understand it's important to keep the heat down and cool the weld

Learn MorePDF STULZ WELDING ELECTRODES - Stulz-Sickles SteelPDF

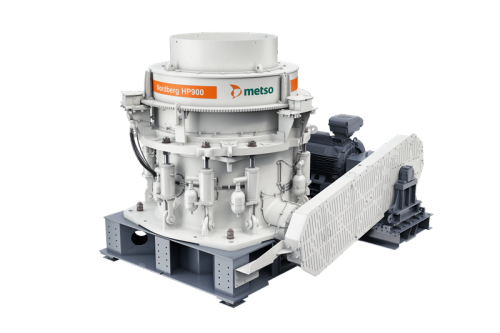

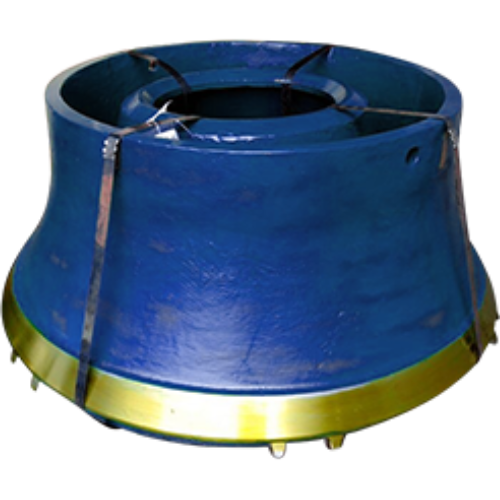

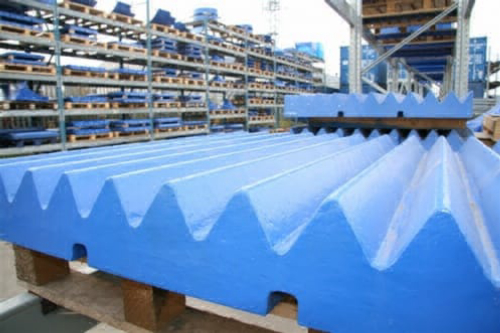

Carbon, low alloy and high manganese steel parts re-quiring protection from a wide range of severe abrasion and impact combinations: Typical examples are shovel buckets and teeth, crusher rolls, jaws, mantles and ham- flex-core welding wire for use with Stulz-Creusabro 4800 & 8000, Stulz Alloy/Wear products and other carbon steels. • Use

Learn MoreWelding of HSLA Steels - TWI

Job Knowledge 98. The development and use of high strength low alloy (HSLA) steels has been driven by the need to reduce costs, the higher strength compared with a conventional carbon-manganese steel enabling thinner and lighter structures to be erected. The majority of these steels are to be found in structural applications; offshore

Learn MoreWelding of Nickel Alloys

Nickel alloys, both cast and wrought and either solid-solution-strengthened or precipitation-hardenable, can be welded by the GTAW process. The addition of filler is usually recommended. Direct current electrode negative (DCEN) is recommended for

Learn MoreWeldability of materials - carbon manganese and low alloy steels

The presence of manganese and silicon in the parent metal, electrode and filler wire is beneficial as they act as deoxidants combining with entrapped air in the weld pool to form slag. Rimming steels with a high oxygen content, can only be welded satisfactorily with a consumable which adds aluminium to the weld pool.

Learn MoreAluminum Spot Welding for Metal Fabrication | Hillsboro, OR

An electrical current passes through two copper alloy electrodes to the sheet surfaces. Those surfaces are usually resistive materials such as low-carbon steels. Spot welding is widely used in metal fabrication projects. Originally, welding was used for steel. Now, aluminum spot welding has become popular.

Learn MoreManganese and nitrogen in stainless steel SMA welds for cryogenic

The U.S. Department of Energy's Office of Scientific and Technical Information

Learn MoreCarbon Equivalent for steel, low alloy, C-Mn steel and cast iron

Carbon Equivalent (C.E) is used in welding to define the weldability of steel and to know how the different alloying elements influence the hardness & microstructure of the material that has to be welded. Considering the C.E. value hydrogen-induced cold cracking of cold cracking in the weld can be predicted according to the EN1011-2.

Learn MoreWeldability of Metals and Alloy Steels - Welding Advice

Steels with a range of 0.35% ‑ 0.6% carbon are heat treatable to higher strengths than mild steel but require special precautions in welding for this reason. These steels, usually also having a slightly higher manganese content (0.6‑1 %) are used for higher strength bar stock in machine frames, shafts, sprockets, and cast steel tractor

Learn MoreMETHOD FOR WELDING MANGANESE ALLOYS

A method for welding alloys of high manganese content to avoid the development of weld flash is shown to comprise the steps of resistance

Learn MoreTIG Welding for Metal Fabrication | Hillsboro, Oregon - Meta Fab, Inc

TIG welding is fantastic for detail, precision, and high levels of control. That means that TIG welding is a good option for small diameter piping and tu , particularly small-diameter and thin-walled tu . TIG welding is also uniquely versatile, with a wider range of materials to choose from than any other welding method.

Learn More