optimum angle for toggle plate of jaw crusher

optimum angle for toggle plate of jaw crusher crusher copper

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn MorePDF) Selected design issues of toggle plate selection on the

The article presents the problem of increasing the performance of the jaw crusher, reducing the crushing power and moment.

Learn Moreoptimum angle for toggle plate of jaw crusher

Optimum Design and Analysis of Swinging Jaw Plate of a Single Toggle Jaw Crusher" Thesis Submitted in Partial Fulfillment of the Requirements Table 3.1: PE400*600 Jaw Crusher

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

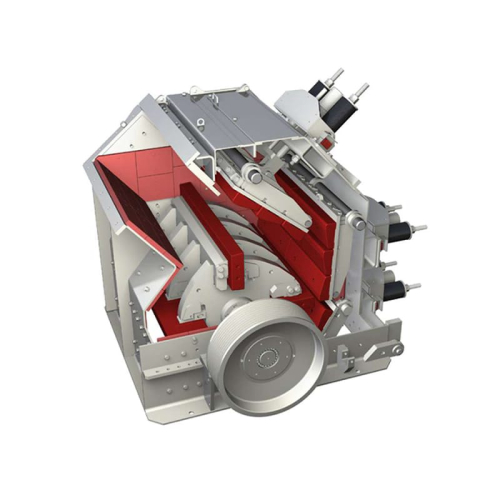

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn Moreoptimum angle for toggle plate of jaw crusher | cone crusher main frame

Applies to over 2200 products worldwide: • Available quickly and worldwide, including for the long term • Expected high Festo quality • Best value

Learn Morejaw crusher best jaw plate material composition

Jaw Plate Material and Composition: Jaw Crusher Plate Component Mn14Cr2, When the moving jaw is up, the angle between lining plate and moving jaw

Learn Moreoptimum angle for toggle plate of jaw crusher | HP800 VIBR SNSR ASSY

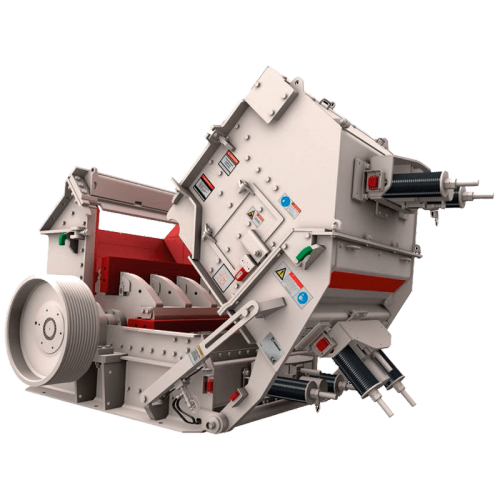

CJ815 JAW CRUSHER. Mar 30, · Each jaw crusher comes with feed hopper, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop. The wide range of jaw plates can be mixed and reversed to ensure optimal, versatile crushing. Your safety is our number one priority. Which

Learn Moreoptimum angle for toggle plate of jaw crusher | crusher spare

Compressive force is applied by two jaws (dies), one of the crusher jaws is Toggle Plate is set at an optimum angle for maximum crushing JAW HEAVY -DUTY crusher hydraulic toggle plate | Pdf Jaw Crusher Toggle Plate. pdf toggle jaw crusher plate bpb35. The Hydraulic Toggle is designed for single toggle or double toggle jaw crushers. read

Learn Moreoptimum angle for toggle plate of jaw crusher | crusher spare

Extension wedges hold jaw dies rigidly across full width • Dynamically balanced flywheels reduce vibration • Toggle Plate is set at an optimum angle for maximum crushing JAW HEAVY -DUTY CRUSHERS lippmann-milwaukee.com 800.648.0496

Learn MoreBasics Of Jaw Crushers - IMS Engineering

The material's output size can be adjusted by adjusting the gap between the fixed and moving jaw plates. This is known as the closed side

Learn Moreoptimum angle for toggle plate of jaw crusher stone crusher

The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity. The accompanying table gives typical outputs for our range of machines, based on dry, free flowing material with a crushing work index of 16 and a bulk density of 100 lbs/cu ft (1600 kg/cu m).

Learn More