crushing efficiency of jaw crusher

What Factors affect the Output of Jaw Crusher? - Luoyang Dahua

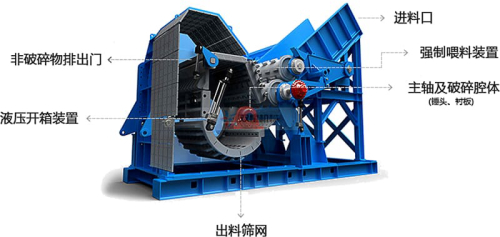

If the cleaning is not timely, the high viscosity materials attached to the inner wall of these crushers will affect the stone crushing efficiency of the jaw crusher. In the selection of crushing materials, according to the working parameters of jaw crusher, select suitable materials with viscosity and water content. * Discharging particle size

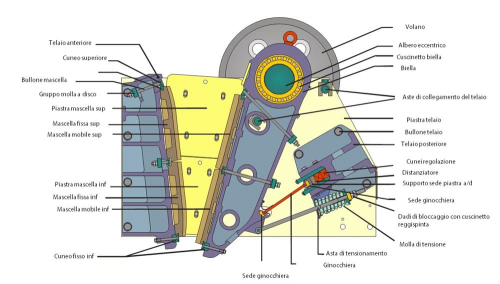

Learn MoreJaw Crusher Working Principle - Mineral Processing

5/6 · jaw-crushers jaw-crusher-manufacturing-and-refurbishing jaw-crusher-efficiency jaw-crushers by L D Michaud January 9, 2022 May 6, Categories Crushing & Screening

Learn MoreJaw Crusher: Mineral process & Sand production | Sotecma

The jaw crushers are applicable in the process of industrial minerals and aggregates treatment. Its most common use is in the process of primary crushing, in

Learn More6 Granite Crushers to Maximize Granite Crushing Efficiency

2022/9/7 · It is an efficient and popular primary crusher for granite. In addition, the fine crushing jaw crusher developed by can also meet the fine crushing needs of granite. Feeding size: ≤1, 200 mm. Discharging size: 10-350 mm. Capacity: ≤2, 200 t/h.

Learn MoreHow to improve the Working Efficiency of Jaw Crusher?

1) connecting rod bearing, eccentric shaft bearing and thrust plate elbow of jaw crusher shall be lubricated by lubrication oil. It is more suitable to use no.70 machine oil in summer and no.40 machine oil in winter. If the crusher is often continuous work, winter uses oil heating device, summer environment temperature is not See more

Learn MoreC6X Jaw Crusher - Shanghai Company

At the same power consumption, C6X Jaw Crusher can achieve higher crushing efficiency. The customer's investment return is even higher.

Learn MoreAssessing the energy efficiency of a jaw crusher | Request PDF

9/1 · Show abstract. Similarly, the crushing of 20 cm feed stock to 6 cm rock would require an energy input of~0.8 kJ/kg. Because the efficiency of comminution equipment is typically less than 10%

Learn MoreJaw crusher crushing sand and gravel with high efficiency

Jaw crushers are widely used in water conservancy, chemical industry, railways, highways and various mining and smelting industries. Jaw crushers have high sand and gravel crushing efficiency. +8613676922906

Learn MoreEfficiency Jaw Crusher For Cement Plant-HN Mining Machinery Manufacturer

Jun 02, Jaw crusher is widely applied to crush high hardness, mid hardness and soft rocks and ores such as ore quartz, granite, limestone, slags, construction materials, marble and so on. The maximum compression strength of materials to be crushed is 320MPA.PE series is used for primary crushing; PEX series is used for secondary crushing and fineContinue readingHigh Efficiency Fine Jaw

Learn MoreHow to improve jaw crusher performance and productivity

3/30 · As excessive wear can cause a 10–20% reduction in production, it is important to find the optimal time for the jaw turn or change in terms of cost and benefit. Again, with the same

Learn MoreAssessing the energy efficiency of a jaw crusher - ResearchGate

It is well known and taken for granted that the efficiency of energy use by comminution (i.e. breaking, crushing, grinding) equipment is

Learn More