crushing circuit

Simplifying the crushing process - Pit & Quarry : Pit & Quarry

1. Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there can be

Learn MorePDF Selection oof Comminution Circuits for Improved EfficiencyPDF

Technically, grinding circuit efficiency refers to the amount of energy used to grind from a certain feed size to a product size as measured against a benchmark, such as that determined by Bond formulae adapted by Rowland (Rowland 1982). From a business perspective, efficiency may be measured according to the cost per

Learn MoreHard coal preparation in a single stage crushing circuit for

main aim was to design the coal crushing circuit, which would produce the a hammer crusher and two-stage circuit based on jaw and roller crushers were

Learn MoreCrusher services - Outotec

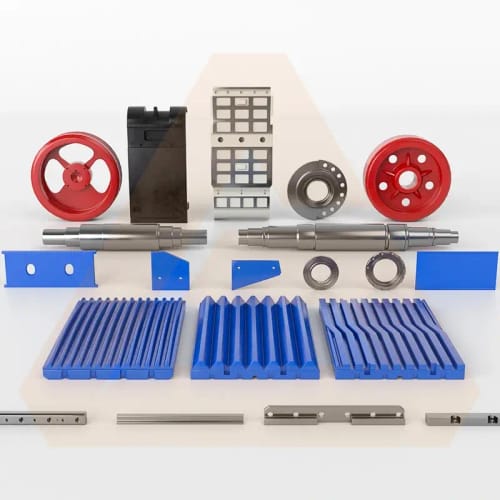

Get the most out of your crushing circuit. Whether you are looking to minimize downtime, increase capacity, lower your cost per ton, or meet specific size-reduction requirements – Outotec can support you. Outotec crushing equipment and process specialists use ore characterization data, comprehensive plant surveys, and

Learn MoreHow To Balance A Crushing Circuit | McLanahan

A balanced crushing circuit provides flexibility with production and ultimately allows you to be more profitable. During this webinar, we look at ways to identify factors that may have your

Learn MoreApplying the Digital Twin to Crushing Circuits | Emerson

of the crushing circuit. Crushing Circuit Modeling. Solutions for crushing circuit units include dynamic models of the following process areas:.

Learn MoreCrushing Circuit Process Control - 911 Metallurgist

For optimization of crushing and screening plant operation, there is one aim, viz, to control the quantity and rate of energy applied to the ore

Learn MoreCrushing Plant Performance Optimization | Agg-Net

Crushing plant layouts can differ considerably from site to site. Plants are designed differently due to variations in the type of rock, the use of the products, the size of the quarry, plant history and many other factors. Both the primary and secondary crushers operate in an open circuit, while the tertiary crusher is installed in a

Learn MoreCrusher - an overview | ScienceDirect Topics

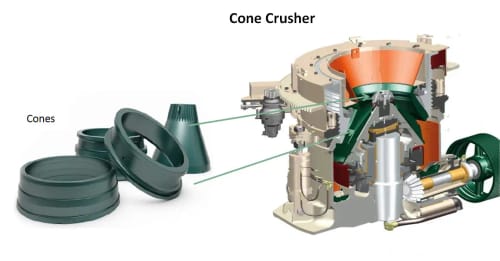

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher

Learn MoreSecondary & Tertiary Crushing Circuits - Mineral Processing & Metallurgy

This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in stages. Again the ore will come from a Primary crusher and be scalped. The coarse material will be crushed by the secondary crusher.

Learn MoreTrio® Crushing Equipment - The Weir Group

We can even help you build an entire crushing circuit from start to finish to maximise efficiency and tonnage. Trio Crushing Equipment | Weir Minerals

Learn More