crusher liners

Cone Crusher Liners - EB Castworld % Cone Crusher Liners

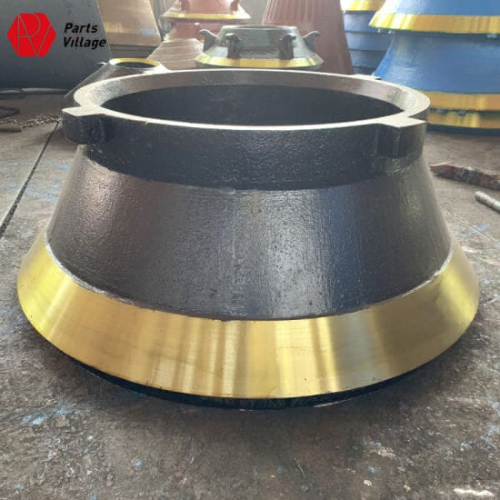

EB uses Mn13, Mn13Cr2, Mn17Cr2, Mn18, Mn18Cr2 to produce Cone Crusher Liners according to the customer’s working environment to effectively prevent the wear during the crushing process and greatly extend its service life. Our Experience: 13 Year Experience in Heat-resistant Steel Field. 18 Year Expertise in Wear-resistant Material Field.

Learn MoreManganese Parts - Australian Crushing and Mining

Our Manganese & Chrome liners are of the highest quality and have been known and proven to consistently out last and out Finlay Cone Crusher Liner.

Learn MoreCone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn MoreCrusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

What We Offer Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts

Learn MoreCone Crusher Liners | Manufacturing and service of

Crusher operating parameters, liner selection, material selection, plant process review, and customer goals all go into providing our customers with the ideal solutions. If more than one

Learn MoreCS Series Cone Crusher Liners - Hunan JY Casting

Hunan JY Casting offers high-quality CS series cone crusher liners for your ® crusher-guaranteed to perform as well as (or better than) OEM crusher parts. Hydroset™-style crushers have been around for decades.

Learn MoreGyratory Crusher Liners

Increase your operation's efficiency with our expert knowledge and high-quality equipment. We are the OEM manufacturer of Gyratory Crusher Liners.

Learn MoreJaw Crusher Plates | Chrome White Iron

Nanhai Heavy Machinery Inc. offers high-quality products for mining like cone crusher liners, jaw crusher plates, chrome white iron protective covers, etc.

Learn MoreJaw Crusher Liners - Makuri Group

A lack of attention to proper jaw design by OEMs results in poor product shape and high steel usage on jaw crushers, although this is easily resolved with the correct design. In some cases, we have seen jaw liners requiring replacement after only removing 5-10% of their initial mass, resulting in a large amount of wastage and excessive liner cost.

Learn MoreBowl Liner - Casteel Foundry

Mining Cone Crusher Parts: Items: Concave, Mantle, Concave Ring, Concave Segment , Bowl Liner,Cone Liner,Arm Guard, Distribution Plate Casting Material: Austenstic Manganese Steel (M14Cr2, Mn18Cr2, Mn22Cr2) Casting Method: Water Glass Sand Casting A

Learn MoreGyratory Crusher Liners

Crusher operating parameters, liner selection, material selection, plant process review, and customer goals all go into providing our customers with the ideal solutions. If more than one option is available, we offer cost-benefit options to make

Learn More