clinker cooler for cement plant

PDF Performance Evaluation of A Grate Cooler in A Cement Manufacturing ...PDF

The specific water flow [kg/kg. clinker] = Net Water Flow [kg/hr] / Total Clinker [kg/hr] 3.1.2 Cooler Output The clinker output from the cooler is expected to be 1 kg provided no loss in mass. 3.1.2.1 Excess Air The cooler excess air was found by measuring the temperature and static pressure at cooler at cooler ESP stack.

Learn MoreThe impact of cooling water types on the cement clinker

The plant includes industrial processes related to the production of white cement. It is using Nile water at different processes such as cooling clinker in the

Learn MoreGrate Cooler – Clinker Cooler | AGICO Grate Cooler In Cement Plant

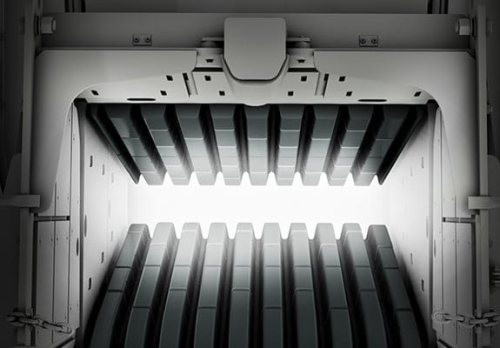

Grate cooler, as a quench type clinker cooler, is the important cement equipment in the clinker calcination system. Its main function is to cool and transport cement clinker. Meanwhile, provide hot air for cement rotary kiln and precalciner.

Learn MoreEnergetic and Exergetic Efficiencies of a Grate Cooler in an

clinkers coming out of rotary kilns. This work focuses on the thermal performance of the clinker cooling system in a cement production plant employing the

Learn Moreinside parts of clinker cooler encyclopedia

Clinker cement Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types In the cooler the air is heated by the cooling clinker so that it may be 400 to 800 °C If part of the fuel necessary to burn the rawmix is burned outside the kiln the output of the system can be increased for a given kiln sizeClinker At the outlet of the kiln the clinker

Learn MoreClinker cooling - INFINITY FOR CEMENT EQUIPMENT

Clinker cooling is necessary because: Hot clinker is difficult to convey; Hot clinker has a negative effect on the grinding Process.

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler for

The grate cooler in a cement plant cools and transports the cement clinker from the rotary kiln, and provides heating air (secondary air) for the rotary kiln and preheater. The performance of

Learn MorePolytrack Clinker Cooler - for Cement Industry and Plants (1 Unit

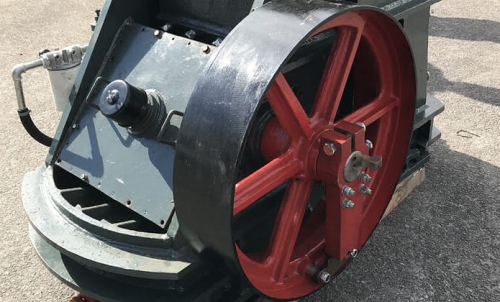

The size of Polytrack® is 6/2,5-2,5, that means 2 grates of 2,5 modules each, 6 tracks per grate (width = 3 m and length = 12 m). The cooler is equipped with a static grate at the kiln chute and with two mobile grates which consist of a total of 5 assembled modules 4 meters in width.The hammer crusher is located at the end of the grates. One of the main advantages of this new type of cooler

Learn MoreReliable, low-maintenance cement clinker coolers

Advanced clinker coolers for your cement plant · Rotary cooler for lithium processing · Heavy-duty Roll Breaker · ABC™ Cooler Inlet · Cross-Bar® Cooler · Grate for

Learn MoreClinker Grate Cooler for Cement Plant

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the cement clinker. At the same time, it

Learn MoreCement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

The thermal efficiency of the grate cooler is 70%-75% and the temperature of secondary air is high, so it is a good choice for large scale cement production. The temperature of cooled

Learn More