jaw crusher double toggle

Double Toggle Jaw Crushers Preview - Rullitech Engineers

Sr. No Name of Equipment Name of Party Size & Type Qty Place 1 Double Toggle Jaw Crusher Balaji Stone Metals 16 x 10 01 No Yerwada, Pune 2 Double Toggle Jaw Crusher shri Ganesh Quarry 16 x 10 01 No kolhapur 3 Double Toggle Jaw Crusher Jayamatha Metals 16 x 10 01 No Kerala

Learn MoreSingle Toggle Jaw Crusher With Unique Benefits

Double toggle jaw crusher is designed for the hardest stones and rocks, tough and abrasive materials, and ferrous metals. But the single one can crush less hard

Learn MoreJaw Crusher Working Principle - StudiousGuy

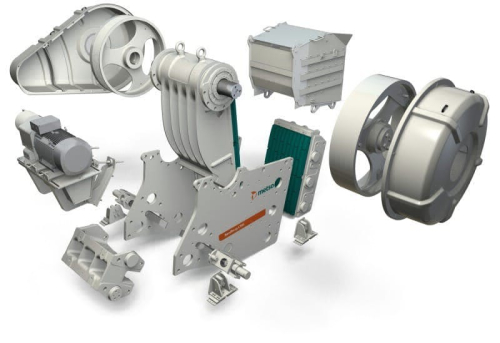

A double toggle jaw crusher consists of two shafts and two toggle plates. The first shaft is the pivoting shaft on the top of the crusher, whereas the other shaft is the eccentric shaft that is used to drive both the toggle plates. Advantages of a Jaw Crusher 1. Jaw crushers are comparatively inexpensive. 2.

Learn MoreDouble Toggle Jaw Crusher – Sagarmatha Industries

BEST KINEMATICS. Optimized Crusher cavity, effective nip angle, kinematics and operating parameters fully guarantee the excellent productivity for which MAXWELL double toggle jaws are known and valued. Cavity area is in accordance with the intake material s.e. Nip angle, which is critical for productivity and trouble free operation is

Learn MoreJaw Crusher – Single Toggle vs Double Toggle - JXSC Mine

Double toggle jaw crusher The upper end of the movable jaw is directly suspended on the eccentric shaft. As the connecting rod of the crank connecting Rod

Learn MoreDouble Toggle Jaw Crusher - Premur Impex - the robust power of 2 jaws

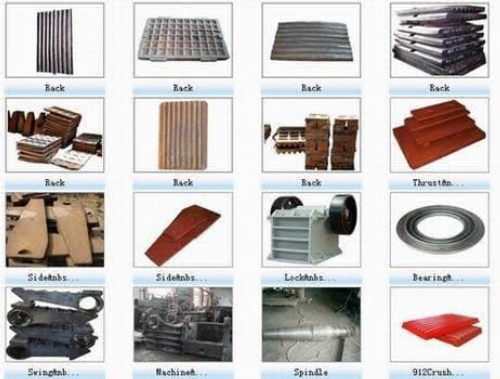

Double Toggle Jaw Crusher Application Primary and Secondary Crushing of Hard rocks, ores and Minerals including Lime Stone, Dolomite, Granite, Iron Ore, Chromite Ore, Ferro-alloy slag etc., with a normal Crushing ratio of 6:1. The crushing action take place by impact of swing Jaw against the stationary Jaw. Capacity 10TPH - 200TPH

Learn MoreDouble Toggle Jaw Crusher | Stone Crusher | Crusher Manufacturer in India

The MechTech Double Toggle Jaw Crusher consists of an eccentric shaft which triggers a Pitman Double Toggle mechanism to move forward the swing jaw that is placed at the hinged top and, to further generate the crushing pressure on the feed material against the fixed jaw.

Learn MoreDT Series Double Toggle Primary Jaw Crusher

Manufacturer of DT Series Double Toggle Primary Jaw Crusher - 3624 DT Series Double Toggle Jaw Crusher, 2415 DT Series Double Toggle Jaw Crusher, 3020 DT

Learn MoreGENERAL REPAIR OF DOUBLE TOGGLE JAW CRUSHER V6

Revamping of Jaw crusher V6-2N. Renovation and machining of pendulum contact surfaces for movable jaw. New pendulum shaft including bronze

Learn MoreJaw Stone Crusher | Single Toggle vs Double Toggle - JXSC Mine

The movement track of each point on moving jaw is more complex in this kind of machine, so it is called a double toggle jaw crusher. Compared with the single toggle jaw stone crusher, the double-toggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber

Learn MoreDynamic Analysis of Double Toggle Jaw Crusher Using Pro

Figure 1 Double Toggle Jaw Crusher Schematic Diagram. In the traditional design process of mechanical products, hand drawing or computer drawing 2D.

Learn More