material properties required in production of jaw crusher liners

Mining Equipment: What are the characteristics of jaw crusher

And the production capacity of jaw crusher is affected by many factors, such as the properties of raw material (hardness, size, and bulk density),

Learn Morematerial properties required in production of jaw crusher liners | mill

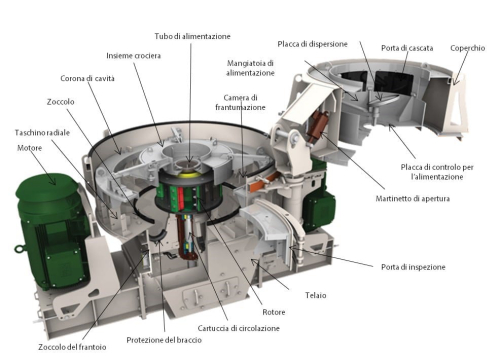

Cone crushers are used in the aggregates and mining industries to crush rock material. The energy required for crushing rocks was obtained by direct measurement of crusher's motor power during By examining the influence of mechanical rock properties on particle size of crushed material it was jaw crusher for silicon materials production

Learn MoreSand Aggregate Production Line for Soft Rock and Hard Rock

2022/9/14 · Three stages crushing and sand making process can be selected. Jaw crusher or gyratory crusher can be selected in the coarse crushing stage according to the material properties and production needs. After coarse crushing, it is sent

Learn MoreLiner wear in jaw crushers

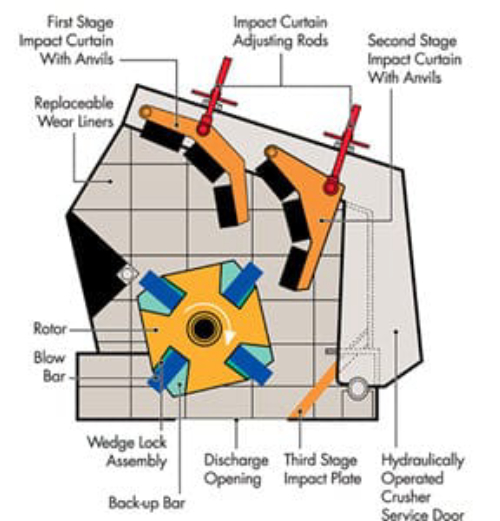

When the material passes through the crusher, it will be subjected to several crushing actions. The properties and performance of the crusher are strongly

Learn MoreCrushing technology - kleemann

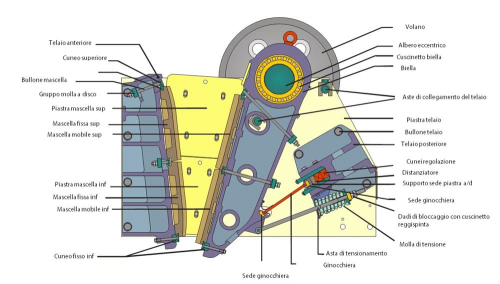

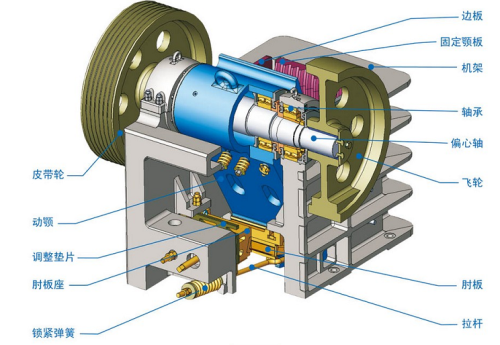

The crushing energy acts on the feed material with strong forces and a low speed. The name jaw crusher is derived from the crusher jaws necessary for crushing

Learn MoreManufacturing and refurbishing of jaw crushers - RocketCDN

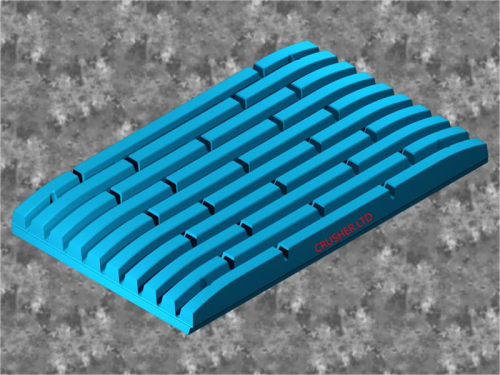

Horsepower requirements can vary from 75 hp to 400 hp. The entire crusher chamber is lined with replaceable 14070 manganese steel liner plates.

Learn MoreJaw Crusher Working Principle - 911 Metallurgist

In particular, very hard rock tends to slip upward rather than break. Choke feeding this kind of material can overload the motor, leaving no

Learn MoreCrusher Wear Parts Selection Guide Rev 002

Wear Parts Materials in Properties. Manganese. Wear Mechanisms in Crushing Chamber. Wear Factors. Feed Material Properties. JAW CRUSHER. WEAR PARTS.

Learn Moretoggle plate seat and toggle plate pictures of stone crushers material

Spare Parts List For Jaw Crusher. Jaw crusher components parts the toggle plates are set at an angle to the arm and the swing jaw as the pitman is revolved the arm is pulled up this causes the toggle plates to come to the horizontal position the movement of the toggle plate forces the swing jaw to be pushed outwards towards the stationary jaw

Learn MoreConstruction, Working and Maintenance of Crushers for

When the swing jaw moves forward, the pressure required to crush the material is generated because the crushing chamber narrows and the material gets crushed.

Learn Morematerial properties required in production of jaw crusher liners

Material Handling / Cranes / AWP Crushing / Screening / Washing / M-Sand Others Attachment Component / Spares Engines / Air Compressors Tyre Lubricants Equipment Rental Equipment Finance Surveying & Testing Miscellaneous Product & Technology

Learn More