plastic extrusion emission factors

PDF PET's next largest application is - US EPAPDF

net emission factors for all plastic types under all materials management scenarios.3 The next sections The plastic resin is then made into products through various processes such as extrusion blow molding (e.g., PET in soda bottles) and injection molding (e.g., HDPE crates). Note again that, due to the

Learn MoreDocumentation for Greenhouse Gas Emission and Energy Factors

emissions per short ton of glass generated for each materials management alternative as shown in Exhibit 1-4. For additional discussion on the detailed methodology used to develop these emission factors, see sections 1.3 and 1.4. Exhibit 1-4: Net Emissions for Glass under Each Materials Management Option (MTCO 2 E/Short Ton) Material Net Source

Learn MorePLASTICS | US EPA ARCHIVE DOCUMENT

WARM includes emission factors for source reduction, recycling, landfilling, and combustion with energy recovery for this material group. The recycling pathway

Learn More2.#56+% 241&7%65 /#07(#%674+0

The use of emission factors to estimate emissions from plastic products manufacturing facilities is an appropriate approach. Development of an accurate emission

Learn MoreDevelopment of Emission Factors for Polyethylene Processing

Emission factors for selected volatile organic and particulate emissions were developed over a range of temperatures during extrusion of

Learn MoreEmissions from processing thermoplastics - ScienceDirect

01/02/1995 · Emissions from processing thermoplastics. A 2-year study has been carried out into the emissions produced during the processing of thermoplastic materials. One of the main reasons for the inception of the work was the perceived need by the plastics processing industry and material suppliers for data in order to comply with recent work-place

Learn MoreDevelopment of Emission Factors for Polypropylene Processing

This study provides quantitative emissions data that were collected during extrusion of homopolymers and copoly- mers of propylene. These data are directly

Learn MoreAP 42 Section 4.4 Polyester Resin Plastic Products Fabrication

However, no new information has come to our attention that indicates the original emission factors for polymer casting (marble casting), pultrusion, continuous lamination, filament winding, and closed molding should be changed. For this reason we are returning section 4.4 to the website with these emissions factors.

Learn MoreGP300 ELBOW ADAPTER GG306-NP20-20, (MALE 1 5/ | plastic extrusion

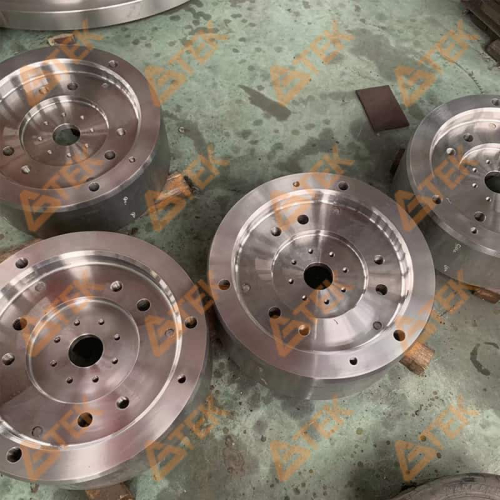

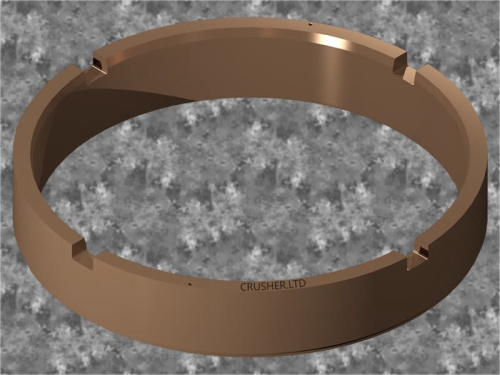

gp300 elbow adapter gg306-np20-20, (male 1 5/ | lt1100 seal ring din7603-a14x18-cu

Learn MoreNational Emissions Standards for Hazardous Air Pollutants

The NESHAP for Reinforced Plastic Composites Manufacturing were proposed on E. What are the HAP emissions factor equations in Table 1 to

Learn MoreAn Environmental Analysis of Injection Molding - DSpace@MIT

Figure 22 - Plastic Demand in Southeast Asia. Table 29 - Main sources of emissions in an injection molding facility 71.

Learn More