rock crusher liners

Eagle® Crusher Replacement Parts - Samscreen

Company, Inc. is an international company that delivers crushing solutions for recycling and aggregate applications. ™ is noted for providing specialized crushing manufacturing solutions. Samscreen, Inc. prides itself on manufacturing products that are customized and fully compatible with machines produced by the leading screener, crusher and trommel

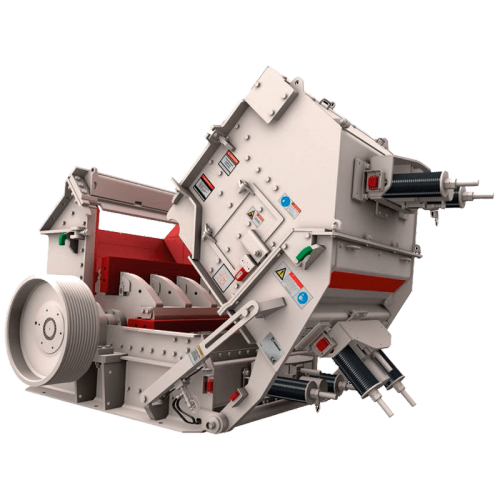

Learn MoreRock Crushers For Sale - Multiple Types For Your Needs - AIMIX GROUP

It has a large crushing capacity, and high efficiency, and is not easy to grind. A jaw rock crusher for sale is a kind of crusher with the longest development time, so its function is more strong, which also further expands the application scope of the jaw rock crusher. APJ-5075E jaw rock crusher Capacity: 40-110(t/h) Model: APJ-5075E;

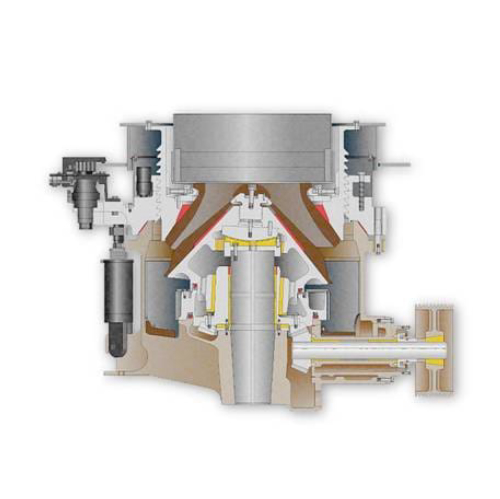

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. Different Liner configurations etc. Key features. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h; Cyclo

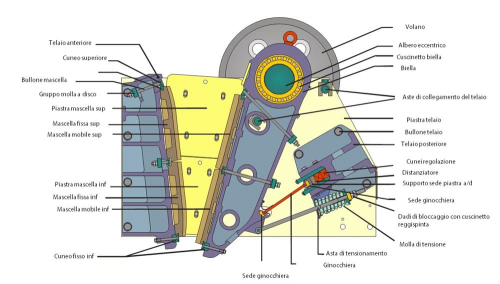

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes

There is one readily discernible difference between the two diagrams we are comparing; the drop per stroke in the jaw crusher diagram is noticeably smaller. This difference is most pronounced in the upper part of the chamber. The reason for the difference is two-fold. In the particular machines selected for these diagrams, there is a difference

Learn Morerock crusher cone liner | muncie m22 rock crusher transmission

EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Work hardening in cone crusher liners. Cone crushers are used in the aggregates and mining industries to crush rock material.

Learn Morerock crusher liners | v-belt sizes chart

Used Crushers For Sale Rock Crushers Machinery and. superior gyratory crusher 54 X 75 54 75 krupp gyratory crusher liners Mobile Crushers all SUPERIOR® gyratory crushers. spare parts cone crushersingapore v-belt sizes in mm hp200 adapter high chromium blow bar for impact crusher lower head bushing 200w laptop charger

Learn Morerock crusher liners gyratory crusher wear inner bushing from columbia steel

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn Morerock crusher liner | crushers plus by mellott

US20050269436A1 - Cone rock crusher. An improved cone-style rock crusher. The rock crusher may be adjusted for varying rock crushing specifications, including different speeds, throws, and liners. The rock crusher comprises a frame that supports a crushing bowl, a crusher head and a shaft, with the shaft being secured to the crusher head.

Learn MoreChange Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use

Learn Morerock crusher liner | crushing equipment copper casting crusher mills cone

The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Change Cone Crusher Liners

Learn MoreLiner wear in jaw crushers - ScienceDirect

01/01/2003 · Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance. A model for prediction of sliding wear was suggested by Archard in 1953.

Learn More