jaw crusher shaft

Alloy Steel Jaw Crusher Eccentric Shaft, Size - IndiaMART

Rakshana Engineering - Offering Alloy Steel Jaw Crusher Eccentric Shaft, Size: 10-12 Inch (Diameter), for Industrial in Hyderabad, Telangana.

Learn MoreJaw Crusher Components & Parts - Mineral Processing & Metallurgy

The first component of the crusher is the drive motor. This will drive a reducer sheave that is attached to an eccentric shaft. On the other end of the shaft is the flywheel. The purpose of the flywheel is to generate energy in the form of motion.

Learn MoreWhat Are the Differences Between The 7 Types of Crushers?

Jaw crusher needs to work together with feeding equipment to complement the crushing process. You can see that the granite material is reduced by the compressive force generated by two jaw dies. Horizontal shaft impact crusher crushing limestone. The mobile crushing equipment in Video is another type of HSI crusher, and it is very hot in

Learn MoreJaw Crushers - MEKA Crushing & Screening Plants

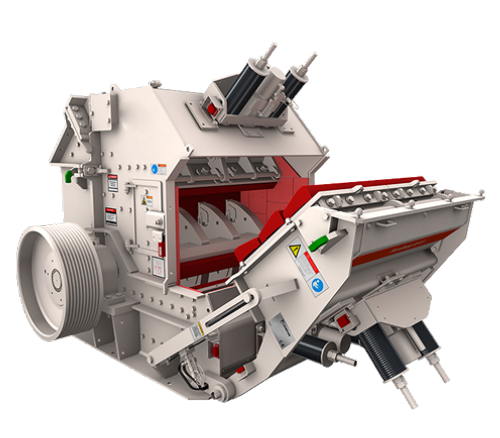

JAW CRUSHER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an

Learn MoreJaw Crusher+eccentric Shaft+assembly

European jaw crusher for sale,mobile jaw crusher 50 ton per . Heightened movable jaw assembly lengthens life of JC jaw crushers.Movable jaw assembly, . Eccentric Shaft Rotation Speed (rpm) 320: 330: 330: 250:

Learn MoreJaw Crusher - Jaw Crusher For Sale - AGICO

Jaw crusher works as a coarse crusher and medium crusher in mining, building materials and infrastructure businesses. Jawbreaker is diversified into three type in accordance with the width of the feed port. Large scale machine’s feed port is above 600MM; medium scale machines are between 300 to 600MM; small scale machines is below 300MM.

Learn MoreCause Analysis and Problems Solving of Jaw Crusher

3The eccentric shaft tightening bushing is loose, causing no gap on both sides of the bearing housing of the frame,

Learn MoreHow jaw crusher works? - Sandrock Mining

3/18 · The jaw crusher crushes materials through the periodic movement of the movable jaw. The crushing method is driven and squeezed. The belt and pulley are driven by the motor, and the movable jaw does a fixed up and down reciprocating movement through the action of the eccentric shaft. When the movable jaw rises, the angle between the toggle plate

Learn MoreKnowing the Basics Leads to Better Care - Timken Company

Like jaw crushers, these machines - common in primary, secondary and tertiary crushing circuits - also operate at moderate speeds under heavy loads and experience signiicant load spikes. In a standard cone crusher, the main shaft is housed in a frame attached to a mantle. A pinion (counter) shaft assembly drives a bevel gear that rotates

Learn MoreAIM: CRUSHING AND GRINDING MAHINERY: - DTE Assam

A typical Blake Jaw crusher is shown in the left hand facing page, a heavy shaft, and this shaft carries at one end the wheel H which serves both as

Learn MoreJaw Crusher Shaft - Sino Coalition

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Jaw Crusher Shaft, Belt Conveyor Products , Conveying Pipe , Snub Roller Conveyor , Head Pulley On Conveyor . We are able to customize the solutions according to your needs and we can easily pack it for you when you purchase.

Learn More