shaft sleeve clearance

Reduction in radial internal clearance Mounting of FAG

directly on the tapered shaft seat О1 or, if the shaft Clearance group d. CN (normal). C3. C4. Shaft. Sleeve. Shaft. Sleeve.

Learn MoreStandard Mechanical Tolerance Table Charts for Shaft - Hole Fits

Class I - Loose fit - Use for all possible hole - shaft applications where function will permit. Class II - Free Fit - Running fits with speeds of 600 R.P.M. or over and journal pressures of 500 lbs/sqin or over. Wobble or shake between mating parts very slight. Part will turn and slide freely.

Learn MorePDF) Experimental Spectral Analysis of Split Sleeve Bearing

Wear is responsible for many problems and large cost in rotating shaft system. Three different clearances configurations using shims have been

Learn MoreHOW MUCH CLEARANCE DO YOUR BEARINGS NEED?

common method of checking clearance is through the use of CLEVITE 77® Plastigage®. For most applications.00075 to .0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. For example, a 2.000” shaft diameter would require .0015 to .0020” bearing clearance (.00075 X 2.

Learn MoreClearance And Interference Coupling Fits - Efficient Plant

The interference fit standard for most couplings made of medium-carbon steel are 0.00050-0.00075 in/in (mm/mm) interference up to 1800 rpm and 0.00075-0.00100 in/in (mm/mm) over 1800 rpm. Table II reflects interference fits used for NEMA-frame-size motor shafts. The purpose of the interference fit with a keyed shaft is to axially locate the

Learn MoreSleeve bearing clearance depends on many factors - Trade Press

A good example of this with sleeve bearing motors is the question, “What's the proper clearance between a shaft and the sleeve bearing it rides in?

Learn MoreOil clearances in white metal sleeve bearings - Eng-Tips Forums

The general rule of thumb is that the bearing diametral clearance should be 0.0015 to 0.002 inches per inch of shaft diameter. so for a 4 inch diameter shaft the clearance would be 0.006 to 0.008 inches diametral. I'll leave the conversion to metric to you. 1 inch=25.4 mm -The future's so bright I gotta wear shades! edison123 (Electrical) (OP)

Learn MoreSleeve bearing clearance depends on many factors - EASA

A good example of this with sleeve bearing motors is the question, “What’s the proper clearance between a shaft and the sleeve bearing it rides in?” Chances are each of us has a rule of thumb for this, probably related to shaft diameter. Some of these may look familiar: One thousandth, plus 1 per in. of diameter

Learn MoreInternal Clearances & Fitting Practices

Internal Radial Clearance of ball and roller bearings is an important parameter in obtaining proper machine operation, optimal bearing life, and a reasonable operating temperature. With radial bearings of the deep groove ball, cylindrical roller, and spherical roller types, the term Internal Radial Clearance - IRC - is commonly employed.

Learn MoreMounting bearings with a tapered bore | SKF

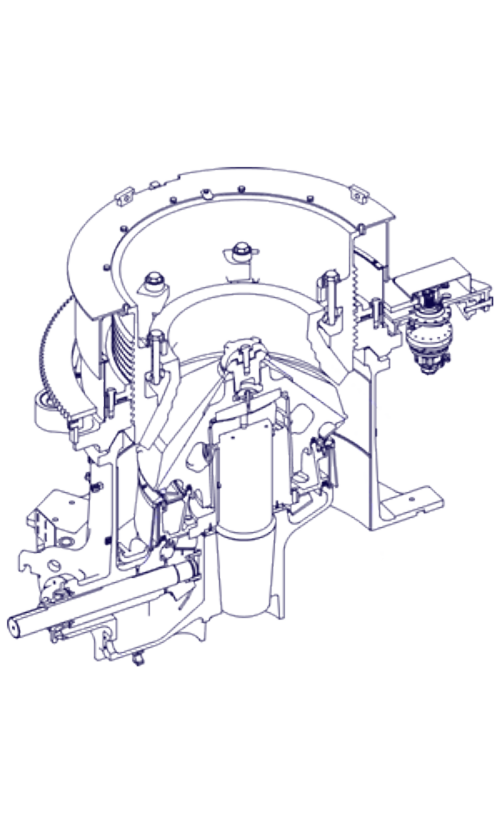

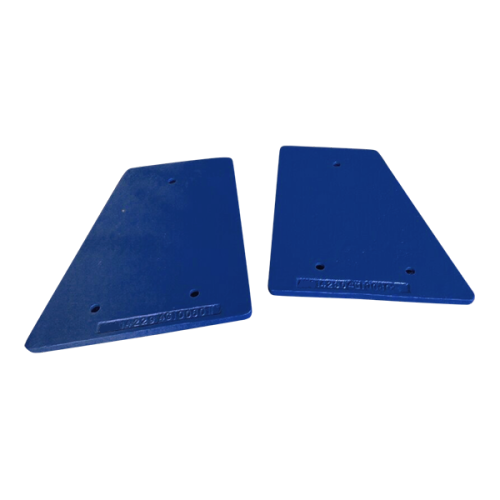

STEP 7. Bearing execution. STEP 8. Sealing, mounting and dismounting. For bearings with a tapered bore, inner rings are always mounted with an interference fit. The degree of interference is determined by how far the bearing is driven up onto a tapered shaft seat or an adapter or withdrawal sleeve. As the bearing is driven up the tapered seat

Learn MoreA Newtonian fluid fills the clearance between the shaft ... - Byju's

A Newtonian fluid fills the clearance between the shaft and the sleeve. When a force of 800 N is applied to the shaft, parallel to the sleeve, the shaft

Learn More