high chromium white cast iron

Chromium white cast iron has excellent stability in high temperature

Long term industrial practice shows that chromium white cast iron has excellent stability and relatively low production cost in high temperature and high wear environment. Therefore, it is widely used in mining and mineral processing, cement production, pulp and paper industry to grind hard materials, such as ore, coal, gravel and cement.

Learn MorePDF] Carbides in High Chromium Cast Irons - Semantic Scholar

High chromium cast irons are widely used as abrasion resistant materials. The mechanical properties and wear resistance of these irons depend on the type,

Learn MorePDF) An Overview on Types of White Cast Irons and High

High chromium white cast irons (HCWCI) are known as abrasion-resistant cast irons and represent one of the most complex microcomposite

Learn MoreMicrostructure of the high chromium white cast iron. (a) (e

Finally, class "D" is composed of materials with the volume fraction of carbides of over 15 vol%, such as high-chromium white cast iron and hard-facing layer deposited on steels or cast irons [10

Learn Morehigh chromium white cast iron nucleation - Metal and Metallurgy

9/27 · I m a material engineer and work in a foundry. we produce high chromium white cast iron abrasive balls. we cannot use %100 returns in smelting due to inhibition of starting nucleation. But we use pig iron for starting nucleation grey-ductile iron smelting. i want to

Learn MoreHigh chromium white iron cast alloy ASTM A532 15/3CrMo or 25%Cr

High chrome white iron cast alloy's superior wear resistance is due primarily to a high volume fraction of very hard, well-dispersed primary and secondary carbides in a matrix of martensite. The high chromium content provides good resistance in corrosive environments and good oxidation resistance. COMPOSITION C % 2.0 - 3.5 Mn % - 1.5 max.

Learn MoreHigh chromium cast iron | Abrasion resistant pipe

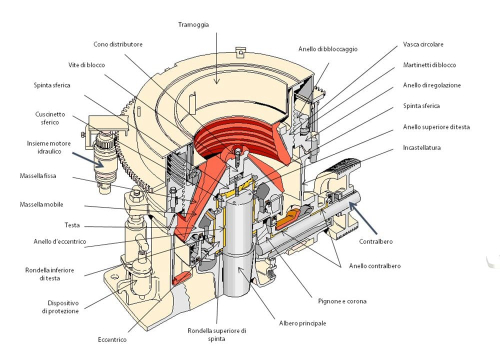

High chromium cast iron is the third generation of white cast iron developed from ordinary white cast iron and hard nickel cast iron. The chromium content of high chromium white cast iron is more than 11%, and the ratio of chromium to carbon is between 4~8. Under these conditions, M7C3 type carbides with high hardness almost completely replace

Learn MorePDF Chapter 1 High Chromium Cast Irons - annualreport.psg.frPDF

cryogenic treatment of sg iron for disc brake application, white cast iron 10 hardness 375 to 600 bhn tensile, microstructure evaluation and wear resistant properties of, aluminum, high chromium cast iron the results on ti added hypereutectic high chromium cast iron can be widely be applied to improvements of wear resistant parts in

Learn MorePDF Wear resistance of high chromium white cast iron for coal ... - SciELOPDF

High-chromium white cast irons are ferrous alloys containing 11-30% Cr and 1.8-3.6% C along with variable amounts of molybdenum, manganese, copper and nickel [1]. The standard procedure most commonly used for the classification of this kind of cast iron alloy is ASTM A532-10 ( ).

Learn MoreHigh-Alloy White Irons :: Total Materia Article

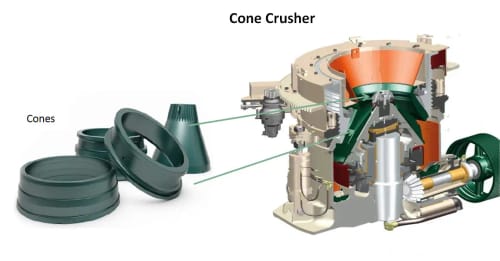

High-Chromium White Irons, The high-chromium white irons have excellent abrasion resistance and are used effectively in slurry pumps, brick molds, coal-grinding mills, shot-blasting equipment, and components for quarrying, hard-rock mining, and milling. In some applications they must also be able to withstand heavy impact loading.

Learn MoreWear resistance of high chromium white cast iron for coal

High-chromium white cast irons are ferrous alloys containing 11-30% Cr and 1.8-3.6% C along with variable amounts of molybdenum, manganese, copper and nickel [1]. The standard procedure most commonly used for the classification of this kind of cast iron

Learn More