crusher backing

Crusher Backing Compound - Manufacturer & Supplier in the UK

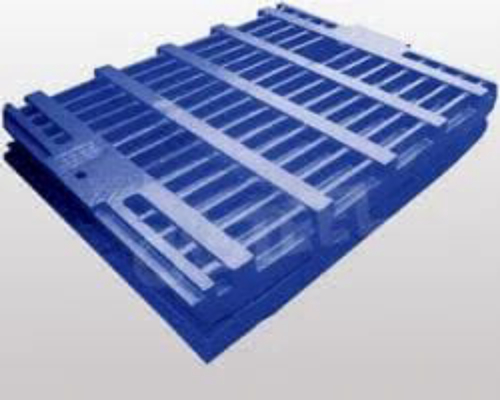

QMS crusher backing is used by many of the world’s most prestigious mining & aggregate production operations for use in their primary gyratory and cone crushers. QMS’s extensive stock holding in the UK allows us to despatch even the largest order promptly worldwide. Categories: After Market Crusher Spares, Crusher Backing.

Learn MoreCrusher Backing Materials Market | Global Industry Report, 2030

The crusher backing materials market is slated to expand at a modest CAGR of ~4% during the assessment period. This is evident since certain companies are developing crushers and grinding mills that do not need crusher backing materials. This may affect revenue sales of crusher backing materials, thus lowering revenue collection.

Learn MoreCrusher Backing Compound - Lumkile

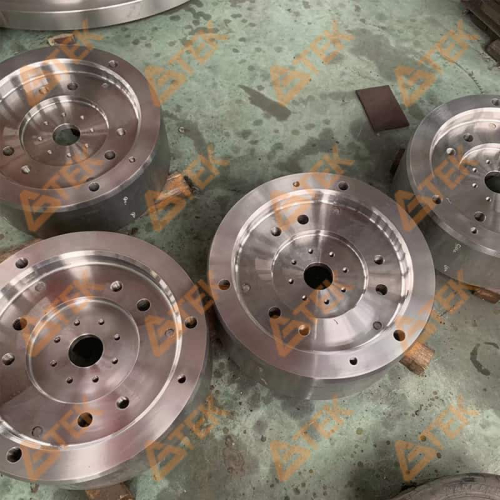

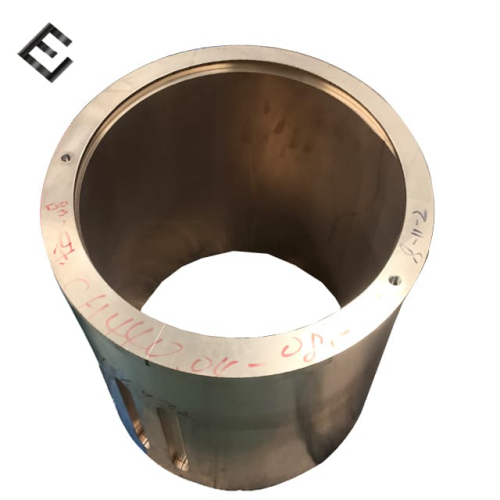

Crusher Back is used for filling cavities between the upper part of crusher and outer jacket and between supporting cone and inner jacket in cone crushers. Typical Applications Cone Crushers Stone Crushers Grinding Mills Autogenously mills Ball Mills Chocking of machinery Foundation bedding Locking Bearings Water Flush Systems. Advantages

Learn MoreK-001 Standard Backing - Copps Industries

Designed for cone and gyratory crushers, REDBAC Standard Backing is recommended for use in most, including severe, crushing applications. The uniform consistency, pourability and cured

Learn MoreCutback Crusher Backing - Cutlass Products

Cutback Crusher Backing Description: 100% solids modified epoxy resin system with unique properties for this particular application. Exceptionally high

Learn MoreCrusher & Backing Compounds - Demech Chemical

Demech's Tuff Crush products are 100% solids epoxy compound system designed for backing wear metal in crushers and grinding mills. Their role is to completely eliminate voids and alignment issues between the liners. The products maintain their strength to ensure all wear linings. It sufficiently protected throughout the crusher maintenance cycle.

Learn More301 High Impact Crusher Backing | Polygem Epoxy

301 High-Impact Crusher Backing is 100% solids epoxy resin system. It is a safe, convenient and economical way to back metal surfaces in all types of crushers and grinding mills.

Learn MoreMegapoxy Crusher Backing I Mining Wear Parts

Crusher backing is used to secure internal crusher parts to minimise vibration, friction, and impact to the equipment during crushing and operation.

Learn MoreCrusher Backing and Grouting - Makuri Group

MAK-BAK Long-life crusher backing MAK-BAK allows the full life of the crusher wear liners to be reached without premature failure of the backing compound. Converting Non-backing crushers to backing We are also able to convert crusher liner design from non-backing to backing style to improve reliability and performance of the liners.

Learn MoreHP300 BACKING COMPOUND | 700 hk32z24 relay wiring diagram

The Global Crusher Backing Compound Market is projected to grow at a CAGR of around 4.2% over the next six years. The key factors driving the growth of the market include; Growing construction sector across the globe, and rising mineral exploration & mining activities.

Learn MorePDF LOCTITE Nordbak Crusher Backing Materials - Kaman Industrial TechnologiesPDF

Standard Mixing Instructions 1. Pre-mix resin for approximately one minute. 2. Prior to opening hardener, shake container thoroughly, mixing the contents. 3. While mixing resin, add hardener contents to resin container. 4. Mix both components together, as directed on the Technical Data Sheet.

Learn More