working principle of gyratory crusher

Explain The Working Principle Of Gyratory And Jaw Crusher

A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of fine material (O'Mahony, 1990). Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an

Learn MoreTorque Analysis of a Gyratory Crusher with the Discrete

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely

Learn Moreworking principle gyratory crusher - ataFinch

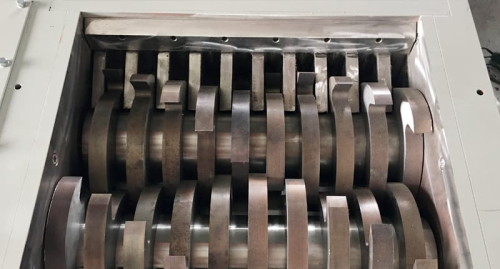

Working Principle of Gyratory Crusher. Gyratory crusher is mainly composedofdriving part, engine base, eccentric sleeve, crushing cone, middle bracket, beam, oil cylinder, hydraulic part, tackle, electrical part, dry and thin oil lubrication part.The space constituted by movable cone and fixed cone is crushing cone.

Learn MoreThe Working Principles Of A Gyratory Crusher

Work principle. The gyratory crusher is a large crushing machine that utilizes the gyratory motion of the crushing cone in the cone cavity of the shell to produce extrusion, splitting and bending effects on the material, and to coarsely break various hardness ores or rocks. The upper end of the main shaft equipped with the crushing cone is

Learn MoreWorking Principle of Crushers - Mineral Processing & Metallurgy

Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position "1." Note that the length of line "1″ from concave to open-side head position, is the same as that of line "O" from concave to close-side head position.

Learn MoreCrushers - All crusher types for your reduction needs

Compressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material. Jaw crushers,

Learn MoreWorking principle of limestone hydraulic gyratory crusher

When the hydraulic cylinder is lifted by pressure, the shaft pin is first cut off, and the crusher stops running, so as to prevent other parts of the machine from being damaged. The weakened section shaft pin on the pulley is the safety device of the gyratory crusher. When large pieces of non-broken material enter the crushing cavity, the large bevel gear with three thrust discs fixed on the

Learn Moreworking and principle of gyratory crusher

Gyratory crusher Working Principle: In gyratory crusher, the top of the spindle with crushing cone is supported in the bushings at beamcentral, the bottom is What is a stone crusher and common types of stone crushers PRLog Nov 29, Cone crusher with the working principle of the same cycle crusher, but only if broken or minor

Learn MoreGYRATORY-CRUSHERS.pdf - RocketCDN

the basic gyratory crusher was developed prior to World War I. of crushers. The same principles are used for either the hydraulic-.

Learn Moreworking and principle of gyratory crusher - Crushing and Screening Plant

Gyratory crusher working principle,rock gyratory crushing Gyratory Crusher Working Principle; Gyratory crushers have a continuous various ores and rocks like working and principle of gyratory crusher 9.6/10· 3.4K Reviews

Learn Moreworking of gyratory crusher

Crushers > gyratory crusher Working principle of gyratory crusher. gyratory crusher form a critical transition between the mine or quarry and the plant. gyratory crusher working gold ore jaw crusher sale,jaw gold crushing machine gold ore jaw crusher began as a pioneer brand of shibang machinery company in the field of crushing

Learn More