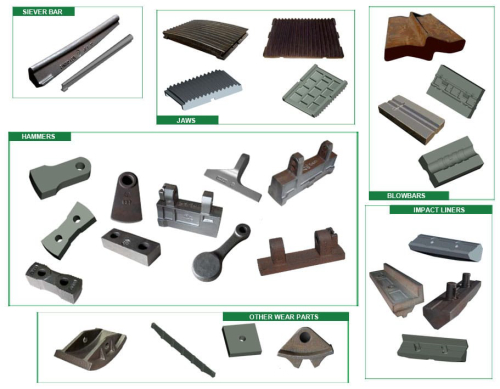

jaw plate crusher

Jaw Crusher - an overview | ScienceDirect Topics

Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws. Therefore, dry particles wedged between level A and level B (Figure 4.4) would leave the crusher at the next reverse movement of the jaw.

Learn MoreJaw Crushers | McLanahan

H-Series Jaw Crushers still use a toggle plate that has the dual purpose of transferring the crushing action and a fuse to protect the crusher's major components. Also used are off-the-shelf bank hydraulic cylinders which provide for tramp iron relief with auto-reset to the last stored set point of the closed side setting.

Learn MoreDesign and Analysis of Swing Jaw Plates of Jaw Crusher

Jaw crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square

Learn MoreJaw Crusher Plates - Wear Parts For Industry | Qiming Casting

Our foundry had succeeded to offer jaw plates for crusher, crusher and other famous brands.On the other hand, Qiming Casting also offer a variety of manganese contents, from 14% up to 22% for the more demanding applications. In some means, we also improve material choice and casting technology. Wedges Wedges

Learn MoreJaw Crusher Liner, Swing and Stationary Jaw Plate

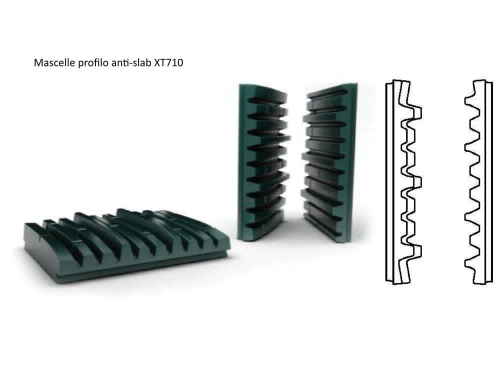

The jaw crusher liner is also called the tooth plate, which is an important part of the jaw crusher. A set of jaws is usually composed of movable jaws and fixed jaws. According to different models of jaw crushers, the jaws also have the same size and model. As the preferred equipment for coarse crushing, the aggregate industry has high

Learn MoreJaw Plate Price

Latest Technology Factory Price Mining Machine Parts Jaw Crusher Spare Parts Tooth Plate Jaw Crusher Liners For Mining Crusher. $1.83/ kilogram.

Learn MoreJaw Plate - Toughing Crusher

03/08/ · Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek

Learn Morejaw crushers for all your needs - Lutze Process

Low jaw plate wear. • Large feed acceptance capability. These four factors are closely linked and the jaw crusher provides a good balance. The de-.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production. It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance.

Learn MoreJual Jaw Plate Terlengkap - Harga Terbaru September 2022

Jaw Plate PE 150 x 250 / Jaw Crusher 1 set. Preorder Tooth Plate Jaw Crusher Penghancur Batu Sparepart 1 Set 2 Pcs PS1218. Rp1.650.000.

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn More