toggle jaw crusher

What Are Jaw Crushers and How Do They Work? | Oreflow

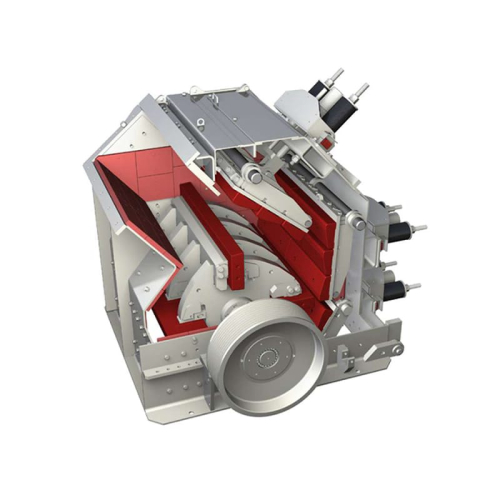

Double-toggle jaw crushers In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down. Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke. The toggle is kept in place by spring-loaded tension rod.

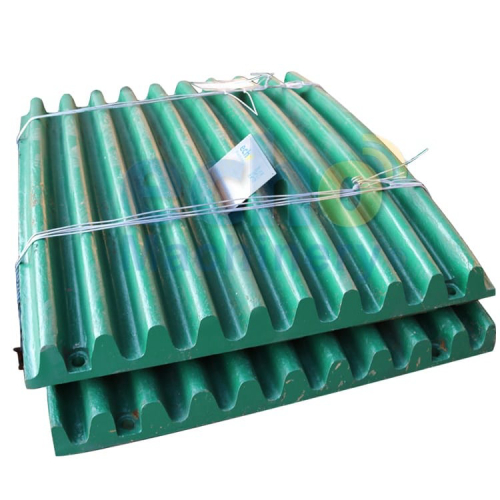

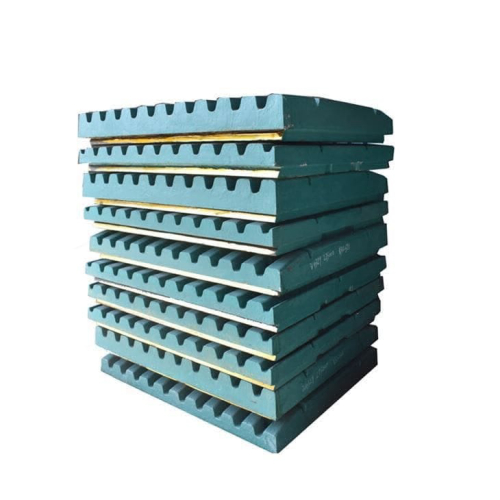

Learn MoreToggle Plate | Genuine Alternative Jaw Crusher Parts | GTEK

If something that the jaw crusher cannot crush gets into the crushing chamber accidentally and it cannot pass through the jaw, the toggle plate will crush and prevent the whole machine from further damage. Minimal maintenance requirements. Inquiry This Item Looking for aftermarket parts? +86 159 5822 9409 / +86 138 6784 5744 [email protected]

Learn MoreJaw Rock Crusher Supplies By Trusted Manufacturer - AGICO

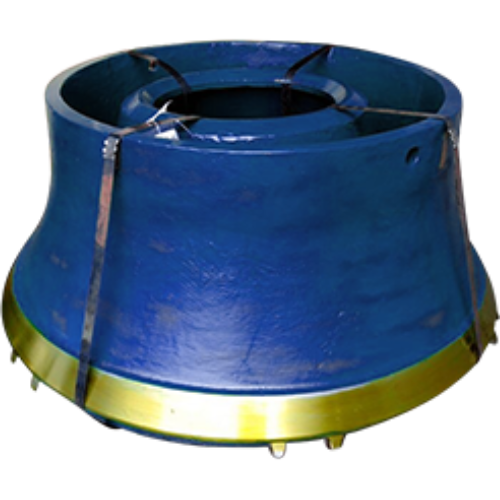

A double toggle jaw crusher has two shafts and two toggle plates. When it works, the moving jaw only involves arc swing motion. Single toggle jaw crusher. A single toggle jaw crusher has one shaft and one toggle plate. The eccentric shaft is on top of the moving jaw allowing the moving jaw to move in arc swing and up down at the same time.

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

A single toggle jaw crusher is a common mobile jaw crusher design. It is suitable for nearly all material types regardless of hardness or abrasion.

Learn MoreJaw Crushers– - TerraSource Global

Additionally, our double toggle jaw crushers do not require massive and costly foundations as do other jaw crusher designs. That's because our jaws are designed

Learn MoreDifference Between Single & Double Toggle Jaw Crusher

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers.

Learn MoreHow does a Single Toggle Jaw Crusher work? | RUBBLE MASTER

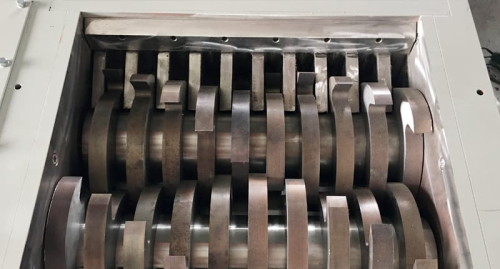

Jaw crushers are used for a variety of natural stone materials: soft and hard stones, highly abrasive rock, ore, and for concrete recycling with lots of rebar. Easy maintenance & low wear Jaw ties and cheek plates last for a very long time and can be changed easily and quickly. A single toggle jaw crusher works like a giant nut cracker

Learn MoreJaw Crusher Toggle Plates vs. Hydraulic Toggle Relief Systems

10/04/ · Earlier in March, unveiled its own hydraulic toggle relief system at CONEXPO-CON/AGG , North America’s largest construction trade show. The hydraulic toggle relief system is available to be equipped onto any jaw crushers and will reduce unexpected downtime, decrease unnecessary replacement costs

Learn MoreJaw Crusher – Single Toggle vs Double Toggle - JXSC Mine

Double toggle jaw crusher The upper end of the movable jaw is directly suspended on the eccentric shaft. As the connecting rod of the crank connecting Rod

Learn MoreSingle Toggle Jaw Crusher - SBM Mineral Processing

SINGLE TOGGLE JAW CRUSHER. A wide range of single toggle jaw crushers STE with a processing capacity range of 2 t/h - 1,100 t/h from the smallest

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force ... - Hindawi

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of

Learn More