spirolox retaining ring installation

SPIROLOX Retaining Ring Install&Removal Smalley - [PDF Document

Internal retaining ring installation is accomplished with a plunger and a tapered bore sleeve. 2. A tapered bore sleeve, which acts as a ring contracting guide, and a plunger pushes the retaining ring into position. 3. Tooling for ring installation should have hardened working surfaces to minimize wear. 6

Learn MoreSPACER H3000 | spirolox retaining ring installation

SPACER H3000 FULL CATALOGUE [email protected] JARI UKKONEN Spacer, Screw, Masking sheet. PACKAGING. Per unit. Per unit. CERTIFICATE H3000 Live.

Learn MoreSMALLEY® SPIRAL RETAINING RINGS - Gandini Fasteners

Manual installation on an individual or low production basis is accomplished as follows: - Separate the ring coils and insert one end of the ring into the

Learn MorePDF Wind Your Way Through Easy Installation - Mark AllenPDF

MANUAL INSTALLATION 1. Separate the ring coils and insert one end of the ring into the groove. 2. Wind the ring by pressing down around the circumference until the entire ring is inserted into the groove. Ease and simplicity of installation are two main reasons to utilize a Spirolox Retaining Ring in your assembly.

Learn MoreSMALLEY® SPIRAL RETAINING RINGS : Installation & Removal

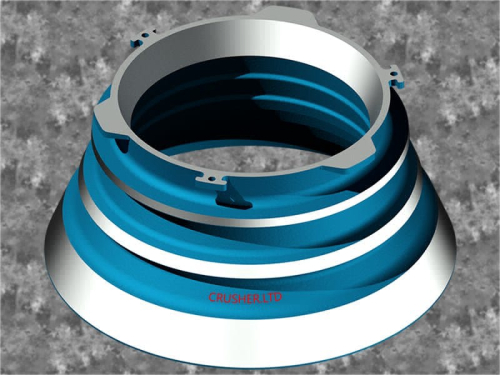

Spirolox Retaining Rings can operate in an internal and an external groove simultaneously. Spiral type retaining rings have many benefi ts for the ID/OD Lock, these bene fits include concealed fastening, no required assembly tooling and a 360° rotational capacity.

Learn MoreAdvantages of Spirolox® Retaining Rings - Smalley - PDF Catalogs

Assembly Methods Manual Installation Manual installation on an individual or low production basis is accomplished as follows: • Separate the ring coils and insert one end of the ring into the groove. • Wind the ring by pressing down around the circumference until the entire ring is inserted into the groove.

Learn MoreDownload Spirolox Installation and Removal Guide | Smalley

Manual installation - Installing the rings by hand provides greater axial flexibility and—after proper training—is the easiest and quickest installation method. • Automated (internal) - We can also create Spirolox rings for use within automated and semi-automated assemblies.

Learn MoreSpirolox-Installation-Guide.pdf

Can't find the ring you're looking for? Call our expert team +44 (0) 1435 866011. Retaining Rings. Assembly Methods. Manual Installation.

Learn MoreRotoPrecision - Smalley Steel Ring Company - Spiral Spirolox Retaining

Quick Specifications. • No gap - Smalley spiral retaining rings offer a full 360° retaining surface. • Over 6000 standard stock sizes from 1/4" to 16" (6 mm to 400 mm) • Specials from .200" to 120" (5 mm to 3000 mm) • Available materials include carbon and stainless steel, Inconel, Elgiloy (to NACE® standards), Beryllium Copper

Learn MoreRetaining ring - 3D CAD Models & 2D Drawings - PARTcommunity

Axially assembled retaining rings are installed into machined grooves in housings/bores (internal) or on shafts (external). These rings are manufactured with lug holes—small holes in the lugs of both axial internal and external retaining rings—that are used to install/remove them, using pliers designed for this purpose. Inverted retaining rings

Learn MoreInstallation & Removal Advantages of Spirolox Retaining Rings

Our rings can easily be installed by hand. First separate the coils, then insert one end directly into the groove, and then wind the rest of the ring into place. This process is the same for internal and external applications. There are also semi-automated and automated processes for installing Spirolox® Retaining Rings:

Learn More