heat treatment of high chromium white cast iron

Heat Treatment Of A532 White Cast Iron

Download Ebook Heat Treatment Of A532 White Cast Iron and practices. All-new sections cover micro- and nano-engineering, robotic vision, alternative energy production, biological materials, biomechanics, composite materials, engineering ethics, and much more.

Learn MoreEffect of Heat Treatment on Fracture Properties of High

ABSTRACT: High-chromium white cast iron contains chromium carbides that provide excellent wear resistance, but also cause poor fracture properties. Heat

Learn MoreHeat Treating of High-Alloy White Cast Irons[1

For castings which will be heat treated, the desired mold-cooled structure is often pearlite. This

Learn MoreHeat Treatment of Cast Irons | 2018-12-12 | Industrial Heating

Dec 12, · High-alloy (e.g., high chromium, high nickel-chromium) white irons can be heat treated. For example, nickel-chromium white-iron castings are given a stress-relief heat

Learn MoreCN102899469B - Heat-treatment method of high

The invention discloses a heat-treatment method of high-chromium wear-resistant white cast iron Cr28. According to the invention, high-chromium wear-resistant white cast iron Cr28 is

Learn MoreHigh Chromium White Cast Iron (High Cr White Iron

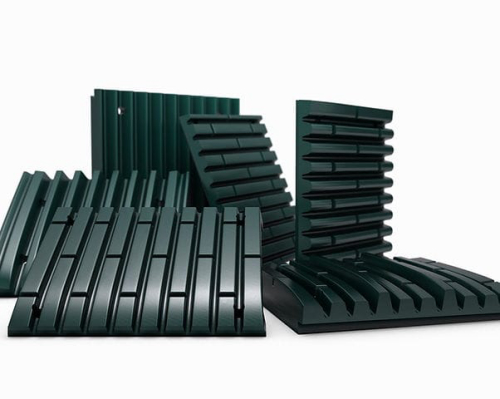

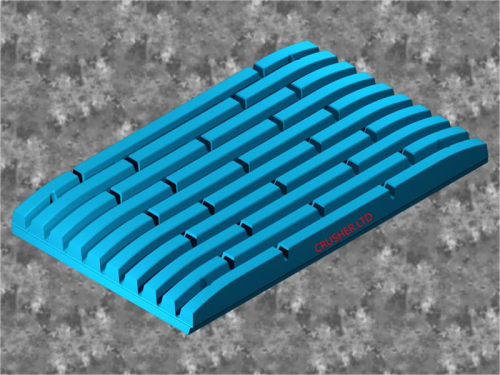

High Chromium White Cast Iron, or High Cr White Iron grades are used in wear applications that require some corrosion resistance. One common application using High Chrome White Iron alloys is in Pump and Valve parts for the Mining industry. The high chromium content offers the corrosion resistance and the fine carbides dispersed throughout

Learn MoreHeat treatment effect on microstructure, hardness and wear

The optimal heat treatment process is 2 h quenching treatment at 1000 °C, followed by a subsequent 2 h tempering at 400 °C. The hardness of HCCI

Learn MoreHeat Treatment in High Cr White Cast Iron Nb Alloy - ResearchGate

University of São Paulo Abstract Wear resistance of high Cr white cast irons can be improved by means of heat treatment. This type of cast iron alloy may present a microstructure with retained

Learn MoreResearch Article Heat Treatment in High Chromium White

In the as-cast condition, the microstructure of high chromium molybdenum white iron consists essentially of dendrites of austenite in a matrix of eutectic mixture of austenite and (Fe, Cr)7C3carbides [ , ]. For many applications, castings are heat treated prior to service to increase the wear resistance as well as impact toughness.

Learn MoreHeat Treatment of White Cast Irons | Metallurgy - Engineering Notes India

The treatment consists of heating the castings to 480-540°C for 8-12 hours, but the temperature and the time at the temperature have important bearings on properties. Excess time or temperature may soften the castings with drastic reduction in the abrasion resistance; whereas, insufficient temperature does not eliminate the austenite completely.

Learn MoreHeat Treating of High-Alloy White Irons :: Total Materia Article

Heat Treatment or Nickel-Chromium White Irons. Tempering is performed between 205 to 260°C (400 to 450°F) for at least 4 h. This tempers the martensite, relieves some of the transformation stresses, and increases the strength and impact toughness by 50 to 80%.

Learn More