jaw crusher gap adjustment

Jaw Crusher BB 100 - RETSCH - efficient and safe crushing

The Jaw Crusher BB 100 is the smallest floor model of the series. It accepts feed sizes up to 50 mm. The gap width can be set stepless from 0-20 mm. Depending on the sample material, particle sizes down to 4 mm can be obtained, resulting in a crushing efficiency of 12.5. The RETSCH jaw crusher series is available in 8 different sizes.

Learn MoreC Series jaw crushers - International Crusher

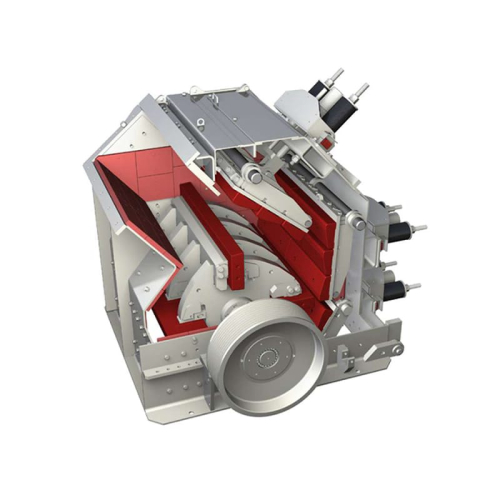

known traditional jaw crusher range that is designed for stationary as well as mobile applications (C80, C100, C3054, C120, C125, C140, C150, C160, C200). The second range is designed specifically to meet the needs of

Learn MoreHow To Adjust Cone Crusher Gap

To complete jaw crusher liner replacement should to avoid damage in cutting cone plate process when the cone lining plate installed the adjustment ring cone at the lower part of the lower lining keep the gap between 1 2 mm between the plate and the cone lining the top installed should be first nut is installed and then cast zinc alloy.

Learn MoreJaw Crusher BB 200 - RETSCH - rapid and gentle crushing

Download. The Jaw Crusher BB 200 is a floor model designed for a throughput of up to 300 kg/h, suitable for many typical crushing tasks. It accepts feed sizes up to 90 mm. The gap width can be set stepless from 0-30 mm. Depending on the sample material, particle sizes down to 2 mm can be obtained, resulting in a crushing ratio of 45.

Learn MoreJacques Jaw Crusher Gap Adjustment Crusher Machine

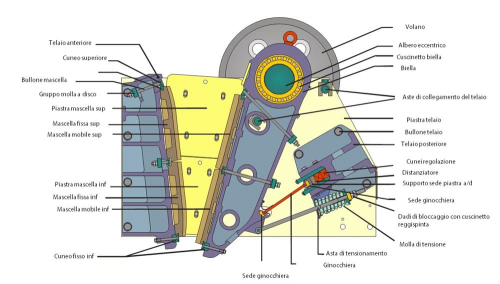

A jaw crusher includes a machine with a moving base a fixed base a crush travel adjusting mechanism for pivotally coupling the top of a crush travel adjusting base to the machine by an eccentric sleeve and an automatic crush gap

Learn Morejaw crusher gap adjustment China Manufacture, Exporter

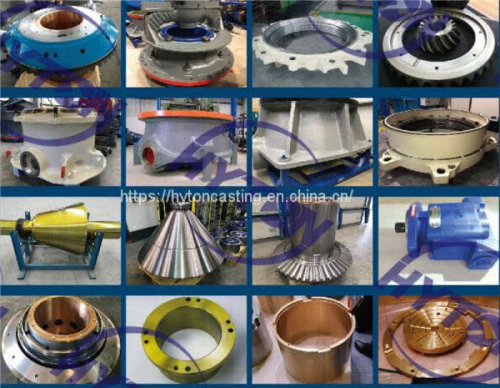

China jaw crusher gap adjustment Manufacture, choose the high quality jaw crusher gap adjustment from China SITE NAME Home About Us Certificates Company Show products Crushing Equipment Cone Crusher Spring Cone

Learn MoreJaw Crusher Gap Adjusting - VCharty Jaw Crusher

A jaw crusher in which in adjusting an outlet gap, manual releasing and applying operations for a tension force of a tension rod are not necessary, and repair of rough of a contact surface between a toggle block and a wedge and frequency of replacement thereof can be reduced. an outlet gap adjusting apparatus for automatically adjusting an outlet gap, the apparatus.

Learn MoreJaw - GIPO B1385 Crushing Rock at a Quarry

The B1385 jaw crusher is compact, track mounted and can be utilised in various applicat Every rock has it own unique rough edges and demands a strong device. The B1385 jaw crusher is compact

Learn MoreCN101940961A - Novel jaw plate gap adjusting device for jaw crusher

The invention relates to a novel jaw plate gap adjusting device for a jaw crusher, and belongs to a novel jaw plate gap adjusting device for a jaw crusher in mining equipment. The adjusting device is characterized in that: the jaw plate gap can be adjusted at any time when the crusher is in a working state, the machine halt is not needed, bolts are not needed to be loosened and supporting

Learn MoreCrusher Close Side Settings - Mineral Processing & Metallurgy

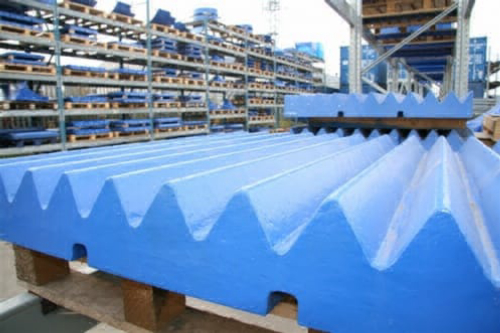

01/17 · The closed side setting can be calculated by deducting the stroke from the OSS. CSS is the most important crusher parameter since it defines the maximum product size and has significant bearing on capacity, product gradation, power draw, and wear. Nip angle. The nip angle is the angle between the fixed and movable jaw dies.

Learn MorePDF Measuring the crusher setting - Metallurgist & Mineral Processing EngineerPDF

However, the adjustment of your crusher is performed at its closed-side setting (CSS). OSS is measured while the crusher is stopped. CSS is calculated by deducting a certain amount (the average stroke) from the OSS. That amount is provided by the table below:

Learn More