tertiary crusher

Patriot® Cone Crusher | Secondary or Tertiary Crusher

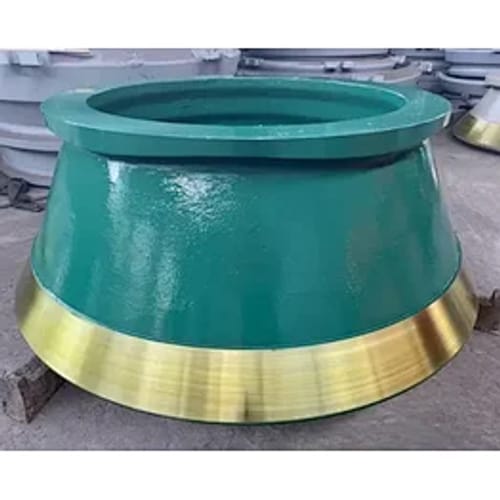

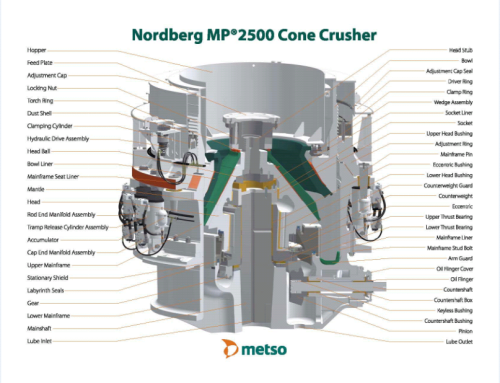

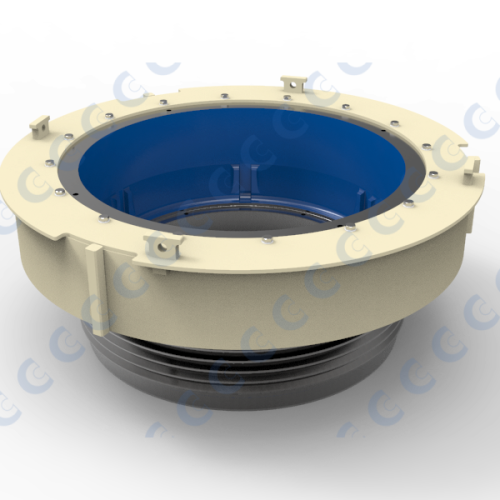

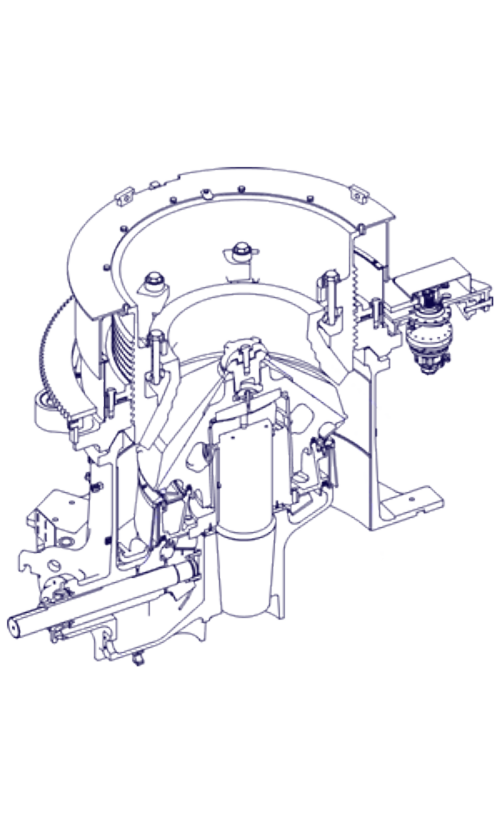

Apr 13, · GUARANTEED FOR REAL LIFE. Typically applied in secondary and tertiary stages, the cone crusher produces reduction ratios of 6:1 to 4:1. Bushing cones, like Superior’s Patriot Cone Crusher, consist of a rotating mantle inside a steel bowl. As rock is compressed between

Learn MoreTK-100 Tertiary Crusher - Stone Crusher Plants

TK-100 Tertiary Crusher TK Series Tertiary crushers characteristically offers a solution for medium hardness materials and belongs the category of rotary impact crusher with it's working principle. Generally, this type of crushers are used as the third crusher in entire system which are the best machines to meet 0-5mm sand requirement of the industry. Tertiary []

Learn MoreTertiary Crushers Market Size 2022 To 2028, With Endless

2 days ago · The global Tertiary Crushers market size is projected to reach multi million by 2028, in comparision to , at unexpected CAGR during 2022-2028 (Ask for Sample Report).

Learn MoreTertiary Crushers - Stone Crusher Plants

TERTIARY CRUSHER Leading the sector with 19 years of knowledge and experience. TK-65 TK Series Tertiary crushers characteristically offers a solution for medium hardness materials and belongs the category of rotary impact crusher with it’s working principle. ROTOR SIZE Ø 1200x650mm CAPACITY 70-120 T/H MAX FEEDING 120mm MOTOR POWER 132-160 kW

Learn MoreTertiary Crushers Market Size, Share - MarketWatch

The Expresswire) -- "Tertiary Crushers Market" Insights 2022 By Types, Applications, Regions and Forecast to 2028. The global Tertiary Crushers

Learn MoreWhat Is Primary, Secondary, and Tertiary Crushing?

There are also tertiary and even quaternary stages of crushing that exist to achieve the finer levels of material reduction. These stages in addition to secondary crushing can often be laid out utilizing an open-circuit portable crusher plant system where processed material is screened and conveyed from one crusher to the next.

Learn MoreTypes of Crushers: What You Need to Know - Machinery Partner

Tertiary crushing is highly valuable in the mineral processing industry. The degree to which a material is reduced largely depends on how fine the material’s final size should be. More rounds of crushing equal smaller-sized results. Screening and multiple crushing sequences can

Learn MoreDifferent Types Of Crushers Machine Of Primary,secondary And

The secondary and tertiary crushing machines resemble the machines used during primary crushing. The two types of cone crushers have different bowl shapes. types of primary

Learn MoreTertiary Crusher|Fine Crusher - Fote Machinery

Tertiary Crusher Introduction. The tertiary crusher is with wide applications range and advanced international technology, and it is the most effective and reliable crushing machine at present, widely applied to fine crushing and medium crushing of grinding materials, refractory materials, cement, silica sand and steel shot.

Learn MoreCrusher - an overview | ScienceDirect Topics

The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig. 13.14), which rotate in opposite directions. The falling feed material is squeezed and crushed between the rollers. The final product passes through the discharge point. This type of crusher is used in secondary or tertiary crushing applications.

Learn MoreCrushing - Outotec

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Outotec equipment is manufactured to meet your material reduction requirements. The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and

Learn More