mantle crusher

CS Cone Crusher Parts Mantle | Crusher Mills, Cone Crusher, Jaw Crushers

quickest delivery time,Simons Cone Crusher Parts,Mantle&Concave Used in Cone Crusher,Good credit standing CS Series cone crusher parts manufacture,High CS Cone Crusher – Pakistan Crusher The CS cone crusher creates a higher value product with less waste. 20-Mantle; 21-Bowl liner; 22-Hydraulic

Learn MoreCone Crushers | McLanahan

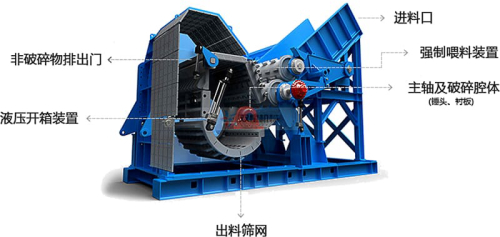

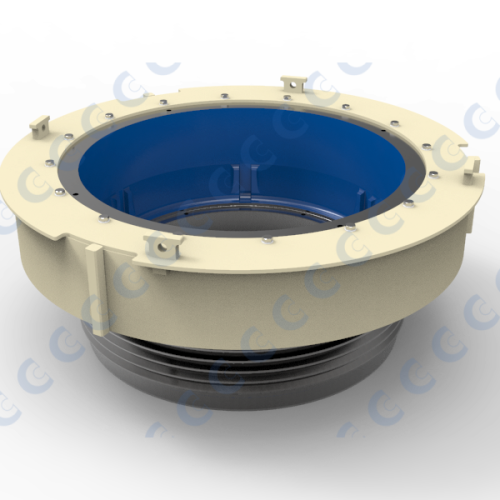

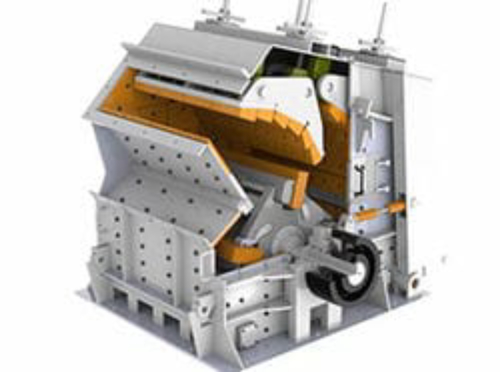

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point. As the wedge or eccentric rotates to cause the

Learn MoreGyratory Crusher - Design of mantle and concaves - Crushing

If you don't keep the crusher choke fed the mantle and concaves will wear to a point where the reduction profile is changed and thus causes higher power draw

Learn Morehow to change the cone crusher mantle?|News-CFTC

28/03/ · Note: the cone crusher mantle of the cone crusher is fixed on the cone body by the cone head, and zinc alloy is cast between them. Therefore, after the newly replaced moving cone works for 6-8 hours, check the fastening condition, and tighten it immediately if it is loose, and the part will cause the runaway due to the insufficient oil pressure or the partial unsmooth oil

Learn MoreHP Crusher Parts Mantle Filler Crushing Backing

HP Crusher Parts Mantle Filler Crushing Backing Compound Apply To Metso. Hyton (Jiangsu) supply the one-stop service for almost all the spare and

Learn MoreCone Crusher Mantle - MGS Casting

Cone crusher mantles are fitted with cone crusher adjustment ring with "U" seal. The mantles and concaves are the crushing parts. So they need exchange when they wear out. Cone Crusher Mantle Material Most of the mantles are cast by high manganese steel. it includes: Mn14Cr2 Mn18Cr2 Mn22Cr2 Mn14Cr2 + TIC insert Mn18Cr2 + TIC insert

Learn Morethe effect of liner we gyratory crushing – a dem case study

PDF | Gyratory crushers are frequently used for first stage sizing in a concave and mantle life cycle when assessing crusher behaviour.

Learn MoreBowl Liner & Mantle | Wear Resistant Crusher Parts | GTEK

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl

Learn MoreCone crusher and cone crusher wear spare parts

HP100 ~ HP800, GP100 ~ GP550 cone crusher mantle, bowl liner. Minyu MSP, MCC cone crusher mantle, concave. C63 ~ C3054 jaw crusehr movable jaw, fixed jaw plate, other jaw plate. [Product features] High strength, low price, long working life. View details Send inquiry. Cone crusher steel parts

Learn MoreCone Crusher Explained - saVRee

How Cone Crushers Work · crushed between the · mantle and · concaves; crushing takes place in the · crushing chamber. As the feed moves towards the drive end of the

Learn MoreCrusher Closed / Open Side Setting Program - Global PAM's

is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle.

Learn More