vibrating grizzly feeder design

How to Build a "Flexi-Perch" Squirrel-proof Birdfeeder for $10 or Less

Hold the feeder by the hanging loop and slide the cap onto the top of the pipe. Your feeder is complete! Hang the feeder so that the bottom is at least 4' off the ground and the feeder at least 18" from the nearest vertical surface. Fill by sliding the top cap up and pour seed into the tube. It doesn't need to be filled up all the way.

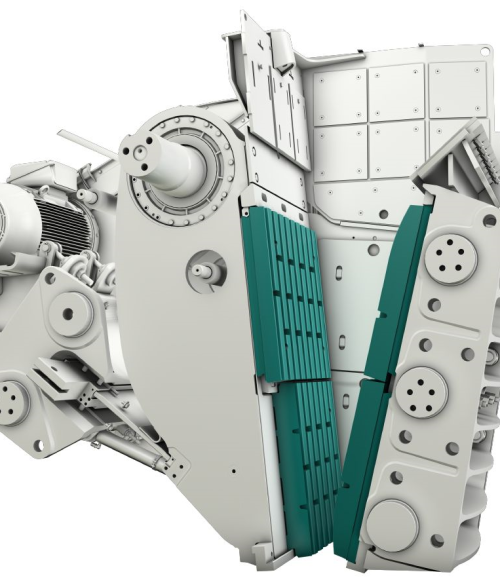

Learn MoreVibrating Grizzly Feeder: Finger-Screen™ | General Kinematics

Features: FINGER-DECKS offer a non-blinding design compared to wire mesh screens. Optional cascading decks improve screening efficiency. Modular decks are easy to replace. Using a single vibratory motor, there is virtually no maintenance required. Will fit into your existing footprint. Can be set-up to feed into your primary crusher.

Learn MoreVibratory Feeder: What Is It? How Does It Work? Types Of - IQS

2022. 9. 9. · Grizzly: This is a heavy-duty screen consisting of bars, rails, Chapter 5: Feeder Trough Design. The capacity of the vibrating feeder depends on the width of the trough, depth of material flow, bulk density of the material, and the linear feed rate. This is expressed by the formula, C = WdR / 4800

Learn MoreVibrating Feeders for Conveying and Dosing • NetterVibration

We have developed vibrating feeders and dosing systems that provide solutions for a wide range of industries and Whatever your product and application may be, we design a totally customized feeder adapted to your needs. Netter Fritz-Lenges-Straße 3 55252 Mainz-Kastel +49 6134 2901-0 info(at)NetterVibration.com. Legal Notice

Learn MoreGrizzly Feeders - Vibramech

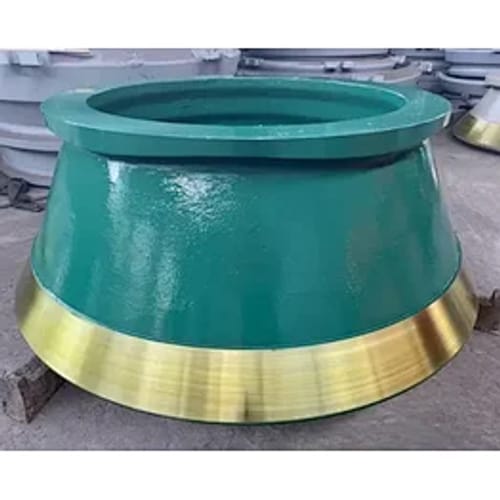

2020. 10. 6. · Vibramech Grizzly Feeders Feature: Sizes ranging in width from 0.6 - 3.0 m, ranging in mass up to 25 tons. Grizzly bars are available in cast manganese; cast manganese –CrMo alloy or wear resistant fabricated steel options. Feed pans can be lined either with rubber impact liners or wear resistant material. Installed on sub-frames where required.

Learn MorePan Feeders - Astec

Astec pan feeders are mechanically driven with a heavy-duty formed deck and are designed to easily replace competitive models. These feeders feature support springs with guards, bolt-in replaceable liners, re-greaseable bearings and exposed exciters for ease-of-access. Additional options include cone discharge spout, rubber liners and variable

Learn MoreVibrating Grizzly Feeder - CPC Crushing and Screening Equipment

Vibrating Grizzly Feeder. Feed Capacity. The capacity of vibrating grizzly feeders is calculated according to the following formula: Q=3600 x f1 x f2 x f3 x L x H x V. where, Q=Feed Capacity in (m3/hr) To obtain capacity in Tons per Hour, multiply by bulk density of the material. Qt = Q x bd bd = 1.6 Tons/m3 for sand and crushed stone; f1 is

Learn MoreVIBRATING, GRIZZLY & PAN FEEDER Manufacturer & Supplier from Dhansura

The Grizzly vibro feeder consists of a very large vibrating body made of thick plate, with inside lining of anti-abrasive plate. The Grizzly vibro feeder is driven by two vibrating motors or eccentric shaft. Salient Features: - Special design of grizzly bars eliminates material clogging and to better sizing effect

Learn MoreVIBRATING FEEDER - 911Metallurgist

2021. 5. 8. · VIBRATING FEEDER. Vibratory feeders are used in gravimetric feeding systems to handle solids with particles that are loo large to be handled by screw, rotary-vane, or vertical

Learn MoreManufacturers of Vibrating Grizzly Feeder for sale India

The Grizzly vibro feeder consists of a very large vibraring body made of thick plate with inside lining of anti-abrasive plate. The Grizzly vibro feeder is driven by two or four vibrating motors. The vibro feeder (which may either be placed on a steel or concrete base) rests on spring. CALCULATION OF GRIZZLY BAR SECTION AREA REQUIRED:

Learn MoreSW Grizzly feeders — SRP

SW Grizzly feeders. SW grizzly feeders are specially developed for mobile and portable plants and small to medium size stationary plants. Compact and high capacity with an effective grizzly design and an optional second deck for fines removal, they are suitable for a wide range of applications. Email us Request a quote.

Learn More